The World’s Leading Ultrasonic Machining Company

We provide unique machining & drilling solutions for hard, brittle, and specialty materials, so your team doesn’t have to compromise its design.

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

Traditional Machining Limits Shouldn’t Hold You Back

Now they don’t have to.

ABOUT Ultrasonic Machining

WHAT IS ULTRASONIC MACHINING?

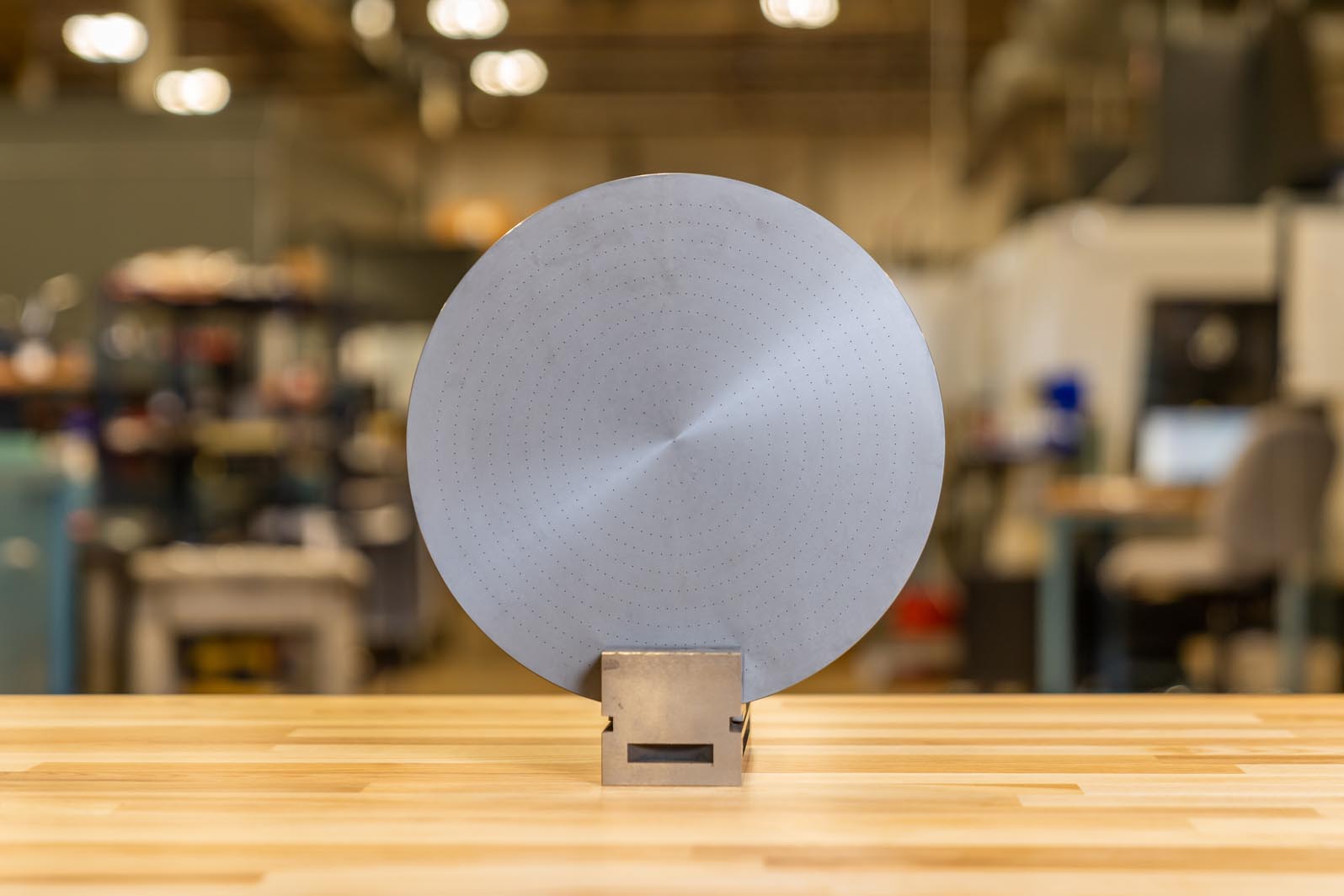

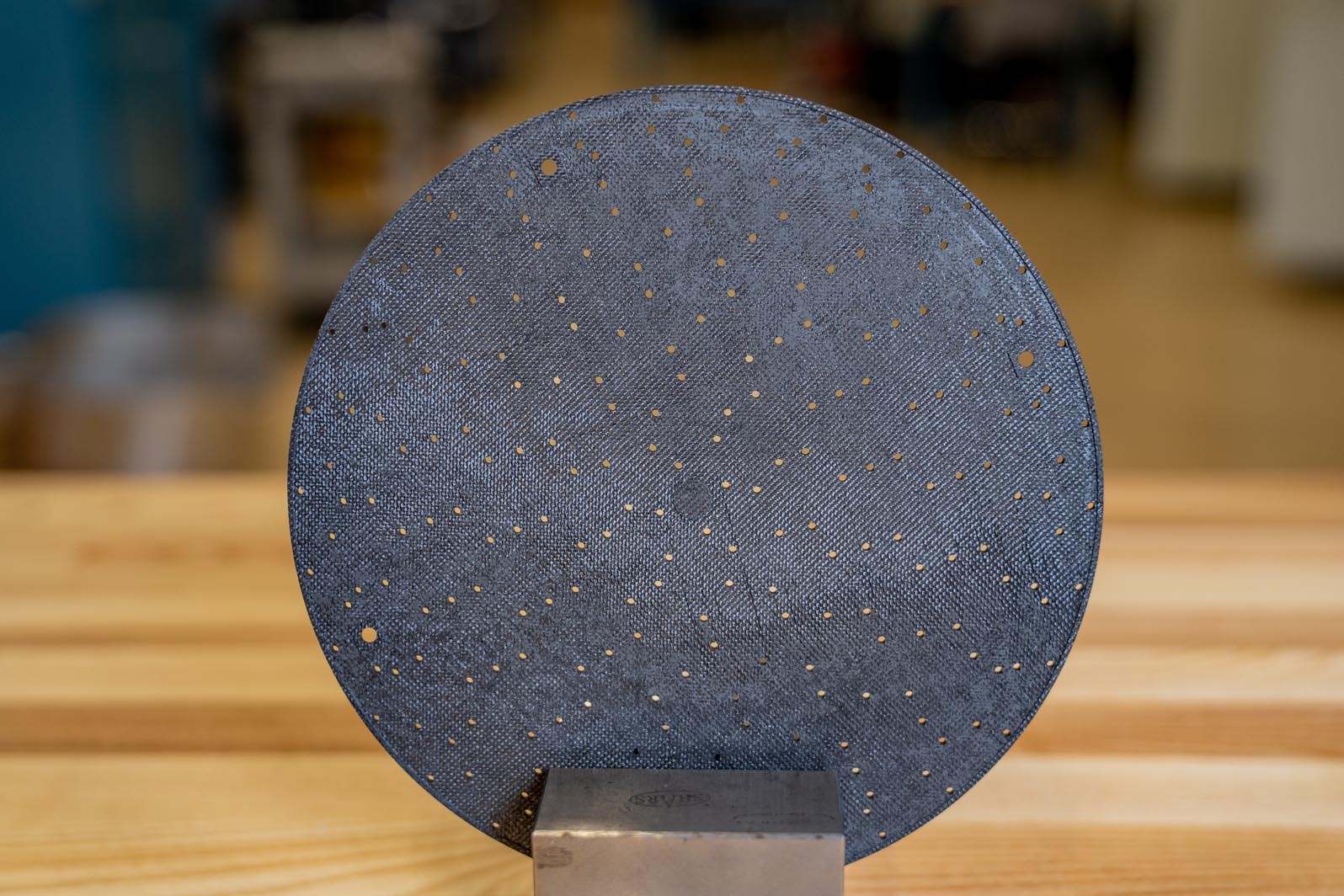

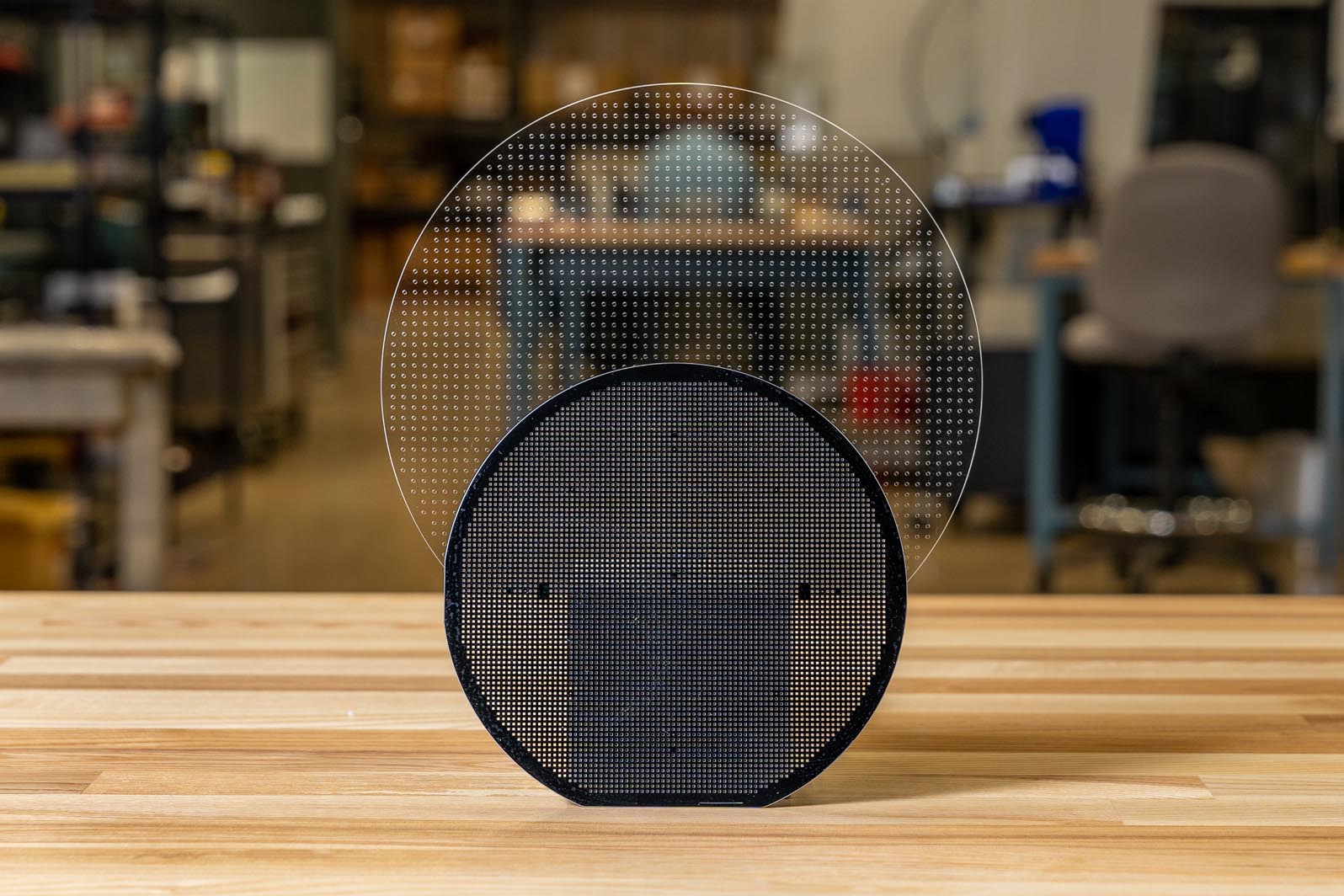

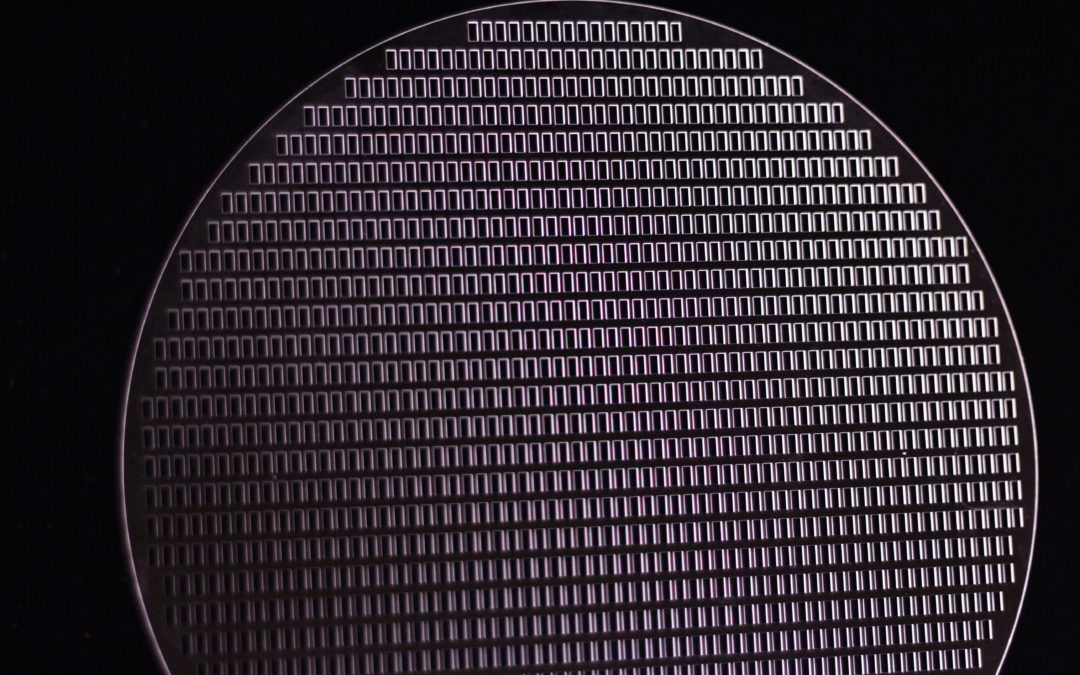

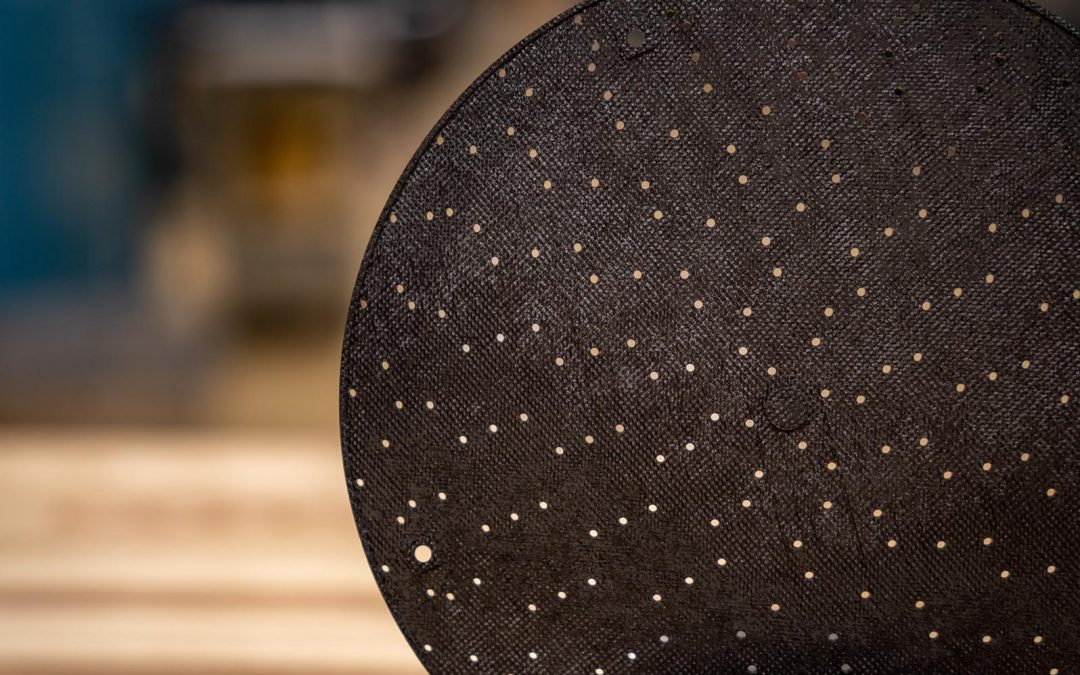

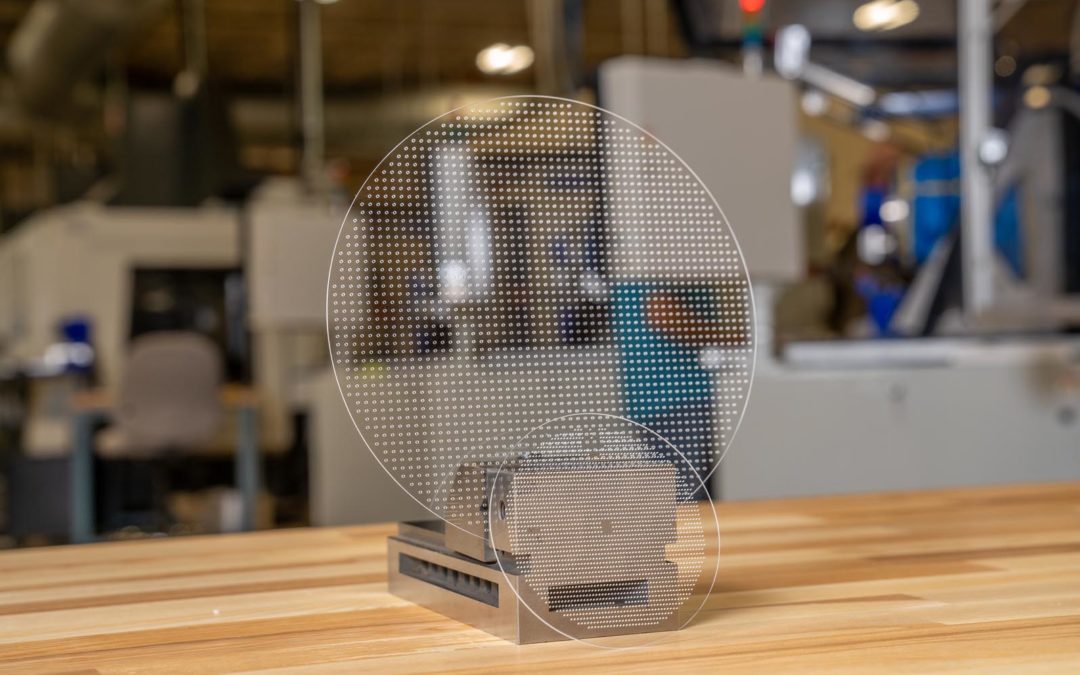

Ultrasonic machining is a loose abrasive machining process in which the mirror image of a shaped tool can be created in hard, brittle materials.

LEARN MORE >

Features and Patterns Possible

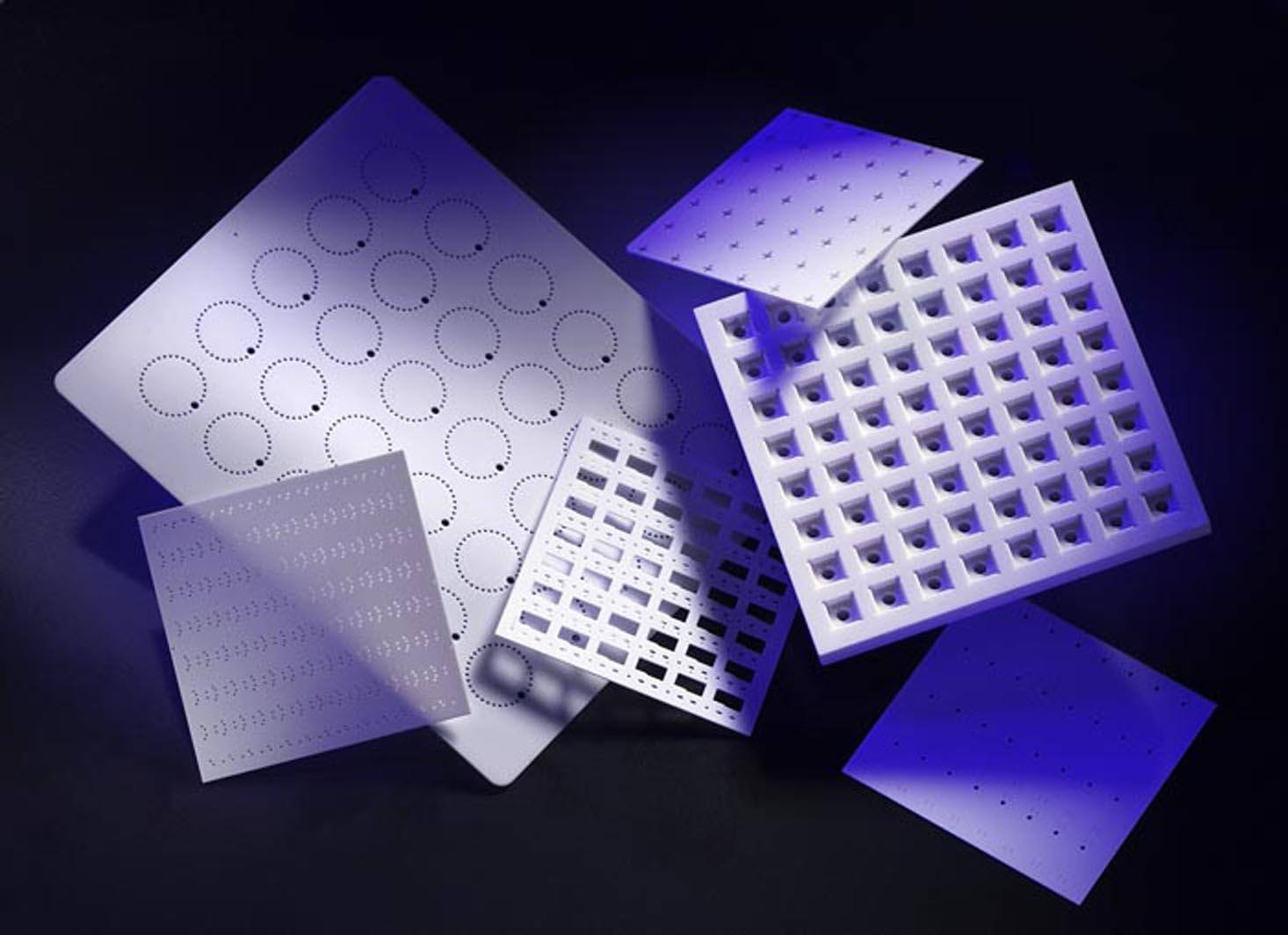

Bullen can machine a limitless number of different cuts and shapes, including:

View List

- Round Holes

- Rectangular Holes

- Odd-shaped holes

- Slots

- Blind Cuts

- Cavities

- OD and ID Work

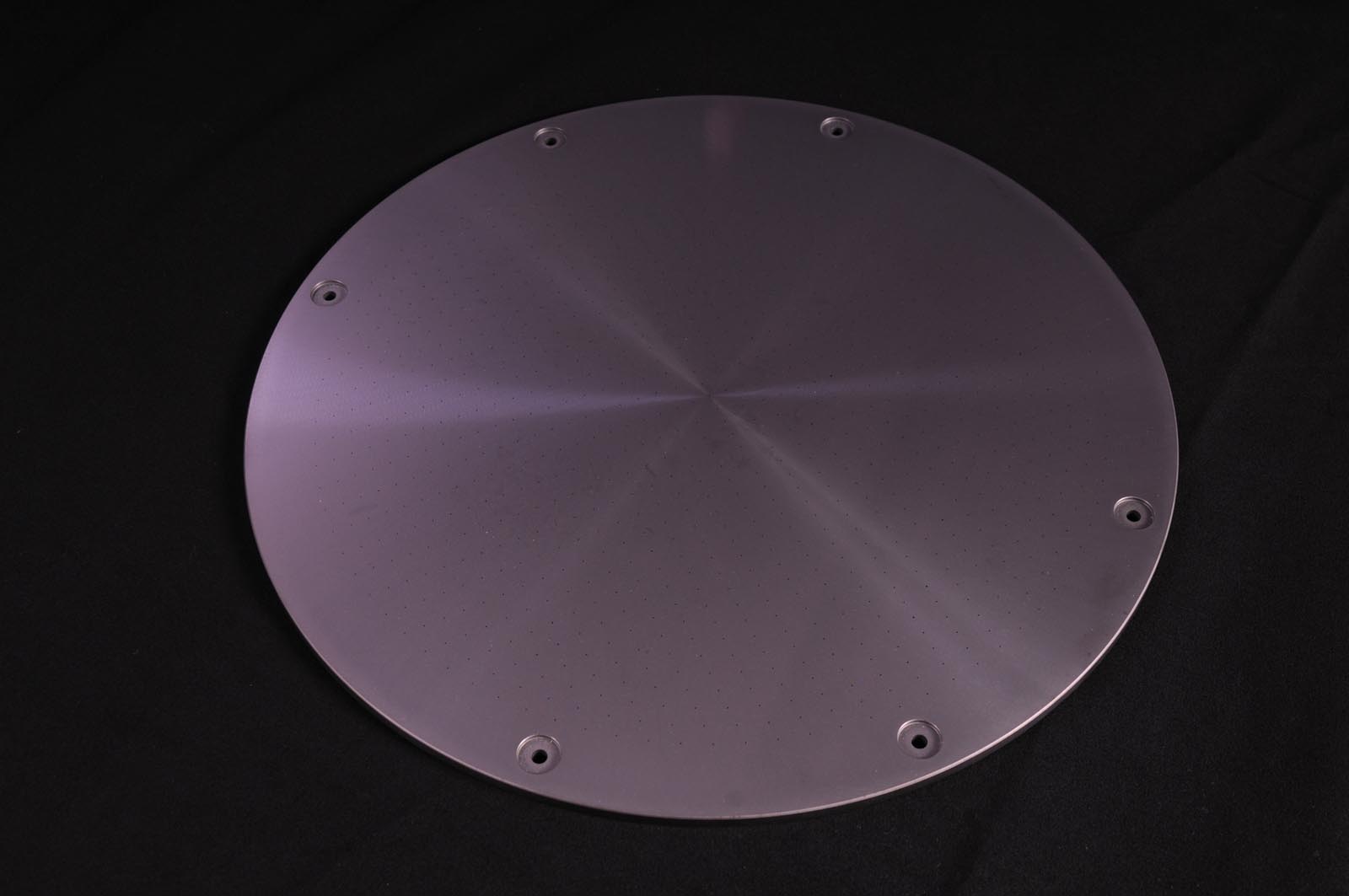

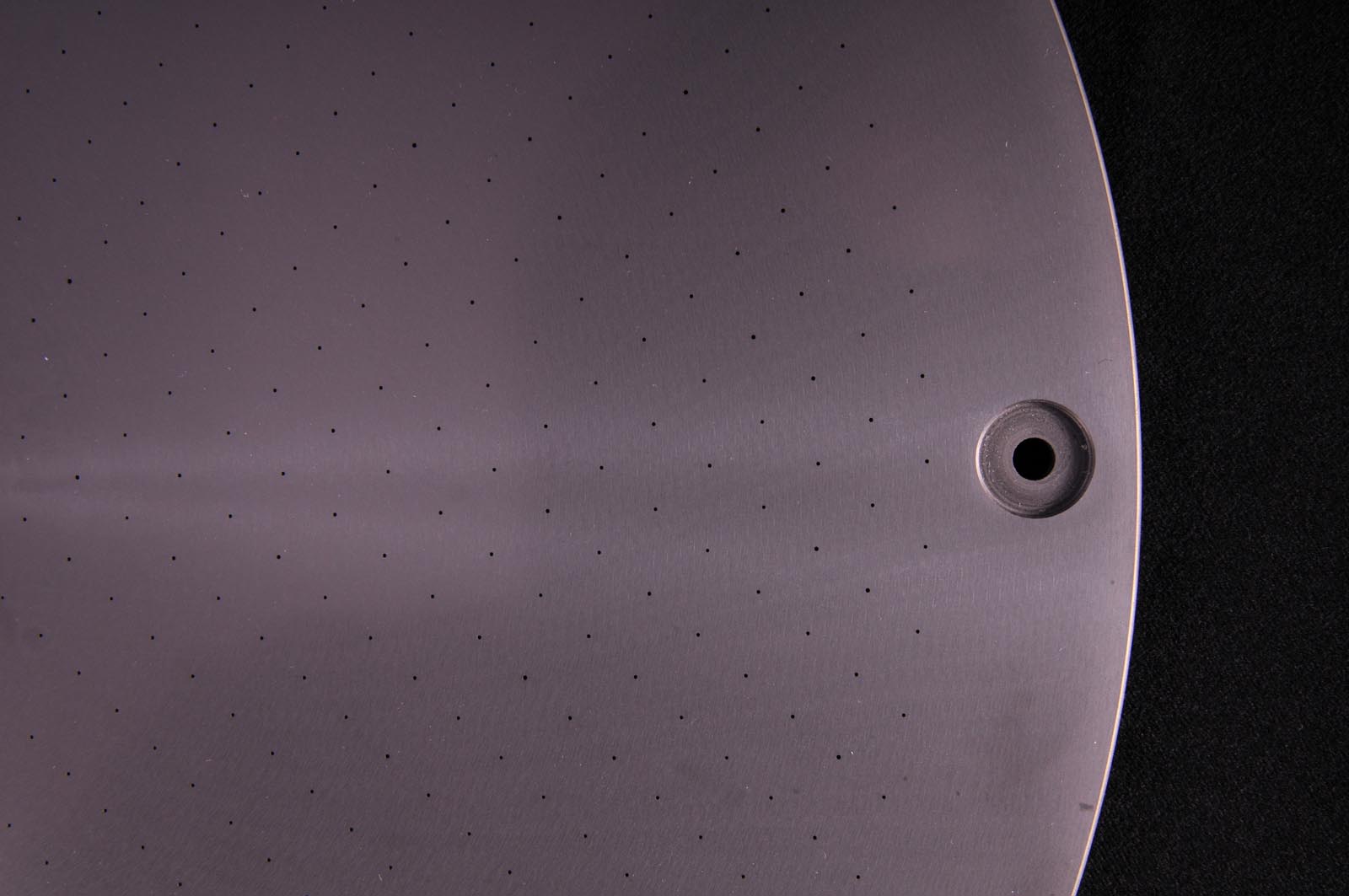

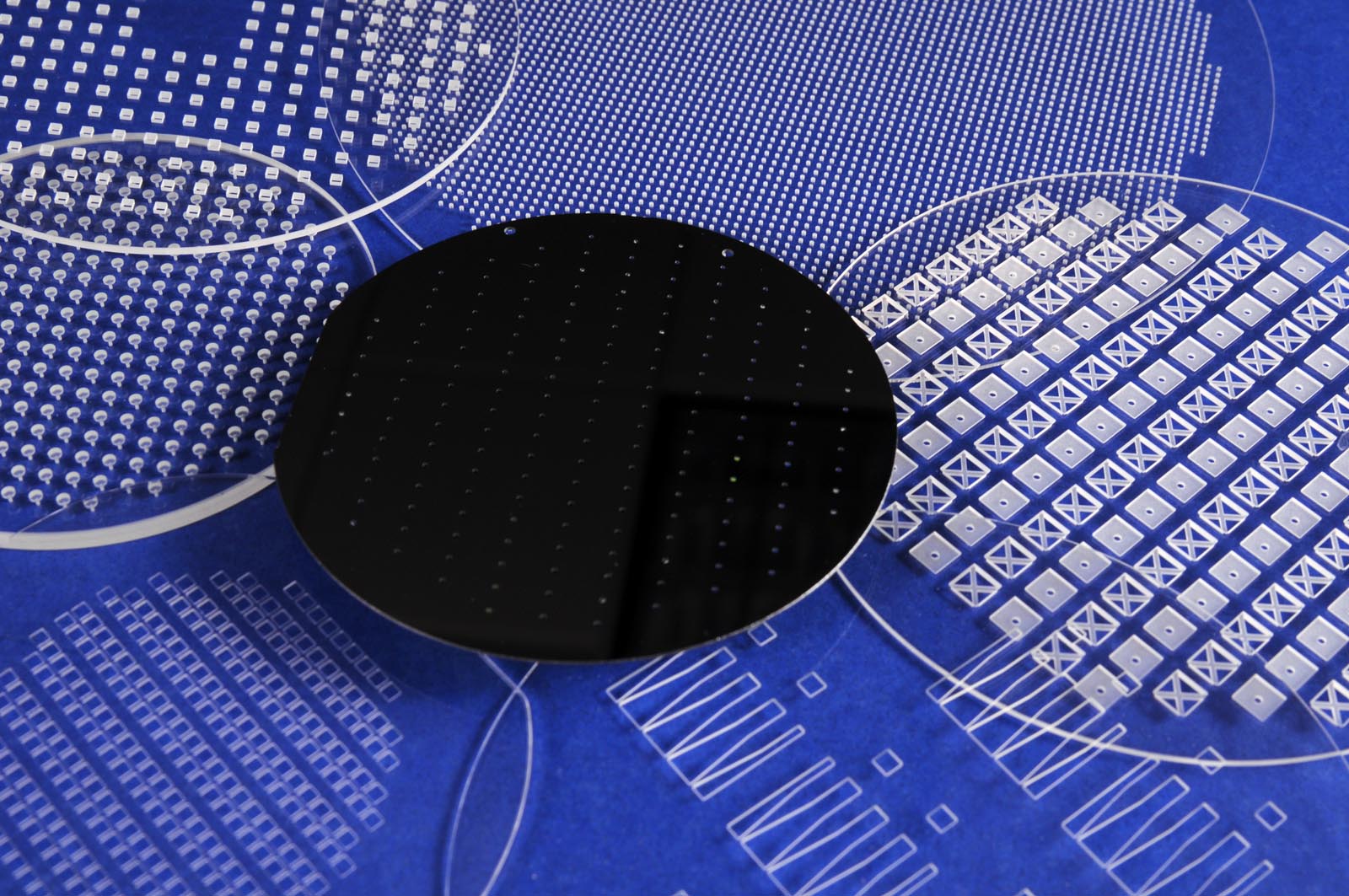

Features ranging in size from 0.008″ up to several inches are possible in small workpieces, wafers, larger substrates, and material blanks.

Aspect ratios as high as 60-to-1 are possible, depending on the material type and feature size.

Applications

Ultrasonic machining broadens the possibilities for your projects

View List

- Tight-tolerance round thru-holes for semiconductor processing equipment components

- Micromachined and micro-structured glass wafers for microelectromechanical systems (MEMS) applications

- Features machined into Ceramic Matrix Composites for Aerospace manufacturing

Advantages of Ultrasonic Machining

Bullen’s Ultrasonic Machining process had many advantages over traditional machining.

The process is non-thermal, non-chemical, and non-electrical, leaving the chemical and physical properties of the workpiece unchanged. This low-stress process translates into high reliability for your critical applications.

High-aspect ratio thru-vias; 60-to-1 aspect ratios are possible in glass and advanced ceramic.

Unlike many competing laser and abrasive blasting processes, ultrasonic machining is able to provide vertical sidewalls, so you don’t have to compromise on your design.

The process integrates well with semiconductor ceramics and MEMS Machined features, and it can be aligned to previously patterned, machined, or etched substrates.

PARTNERING WITH

GLOBAL ADVANCED TECHNOLOGY COMPANIES

FOR OVER 50 YEARS

Fortune 50 Companies

Aerospace & Defense Companies

Mems & Microsystem Developers

Medical & Life Sciences Organizations

Semiconductor Equipment Manufacturers

Materials We Machine

Glass

Fused Silica: HPFS® Corning 7980, Schott Lithosil®

Quartz

BK7, Soda Lime, and other glass materials

Glass Ceramics

Macor

ULE Glass

Technical Ceramics

Aluminum

Nitride

Boron Carbide

Silicon Carbide

Silicon Nitride

Zirconia

Yttria

Sialon

Ferrite

Titanium Nitride

Engineered Ceramics

Converted SiC

PCD

Ceramic Composites (CMC)

Single Crystals

Germanium

Sapphire

Spinel

SiC

Calcium Fluoride

Engineered Plastic

PMMA

Bismaleimide

Polystyrene

Polycarbonate

A Simple Process to Solve Your Complex Engineering Need

1

Talk to Our Team

2

plan

3

Prototype & pilot

4

produce

News

When looking to take the first step towards your engineering career or a career in manufacturing, there are many options. Some paths include: Technical training with a pre-apprenticeship or internship. Apprenticeship with focus on specific education and on-the-job training. College degree with internships Each of these paths open opportunities for an engaging and exciting career […]