ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

your trusted partner

Bullen matches the appropriate machining technology, methods, and materials to create solutions to your most difficult challenges – no matter your industry.

Semiconductor

Automotive

Defense

Aerospace

Medical

Life Sciences

Telecommunications

We Believe You Deserve a Better Solution for your CMC Design

Bullen’s Ultrasonic Machining process is a non-thermal method, creating no HAZ (Heat Affected Zone) and little to no subsurface damage. As a result, no post-machining polishing is needed to relieve residual stress and slag caused by laser machining or EDM. That means a faster and more cost-effective process for your team.

Preserve Material Reliability

The substrate material’s chemical and physical properties remain unchanged.

Expand Design Possibilities

Implement feature sizes not possible with laser machining on thicker substrates.

Optimize Production

Eliminate inefficiencies that slow down production and increase the cost.

MACHINING SOLUTIONS WITH ENDLESS APPLICATIONS

Read below to learn more about just some of the application solutions we’re providing our clients.

machining limitations shouldn’t hold you back

bullen offers unique capabilities beyond traditional machining

Our proprietary capabilities deliver viable solutions to complex engineering problems.

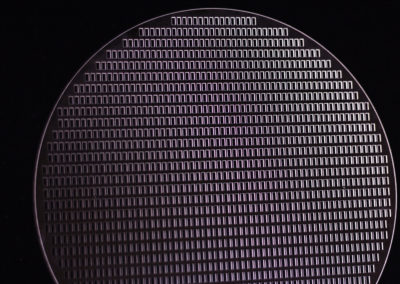

ULTRASONIC MACHINING

The world’s leading Ultrasonic Machining company, Bullen provides a superior solution to traditional machining when your design requires a feature or pattern in certain hard, brittle, & specialty materials.

Explore Ultrasonic Machining >

MICROLUCENT® MACHINING

Bullen uses unique laser technology to cut precise features in transparent materials. This proprietary technology lowers costs while improving the quality of cuts.

Explore Microlucent® Machining >

why bullen?

At Bullen, we don’t just drill your part – we begin with final production in mind, providing state-of-the-art, high-quality, wafer-level machining. Our dedicated team of engineers will:

-

Consider your unique needs.

-

Seek ways to drive down costs and increase efficiencies.

-

Build custom machines to mass-produce your part if needed.

-

Provide a quick turnaround on RFQs and jobs to accelerate your development activities

-

Support your development initiative with custom customer-based R&D

Our wide range of machining capabilities enables us to help transition your design from prototype to full-scale production efficiently and cost-effectively.

News

From Controls Engineer to Manufacturing Leader: How John’s Career Was Built on Grit, Growth, and Learning from the Hard Stuff Not every career path is straight—and John will be the first to tell you that’s a good thing. John started out like many of us—trying to pay for college, working a co-op job at […]