Semiconductor Ceramics

Semiconductor equipment manufacturers, fabricators, and ceramic material manufacturers rely on Bullen for precision machining & Drilling of critical ceramic components for semiconductor process equipment.

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

You’ve Perfected the Design – Don’t Compromise it

Bullen’s extensive knowledge in the machining of glass and ceramics, combined with unique ultrasonic machining capabilities, enables us to provide custom, high-quality, cost-effective solutions that meet the strict requirements of the semiconductor industry.

Conventional Machining

(Laser, EDM)

Higher Part Costs

Lower Process Yield

Common Processing Defects

Subsurface Damage

Longer Process

Bullen Ultrasonic Machining

Reduced Part Costs

Higher Process Yield

Greater Design Reliability & Quality

Little To No Subsurface Damage

Reduced Downtime

We Believe You Deserve a Better Solution for your semiconductor component

Preserve Material Reliability

The substrate material’s chemical and physical properties remain unchanged – Non-thermal method results in no HAZ (Heat Affected Zone) and little to no substrate damage.

Expand Design Possibilities

Implement feature sizes not possible with laser machining on thicker substrates. Micron-level accuracy widens the range of capabilities.

Optimize Production

Eliminate inefficiencies that slow down production and increase the cost. Trust in a faster and more cost-effective process.

BULLEN Semiconductor Capabilities

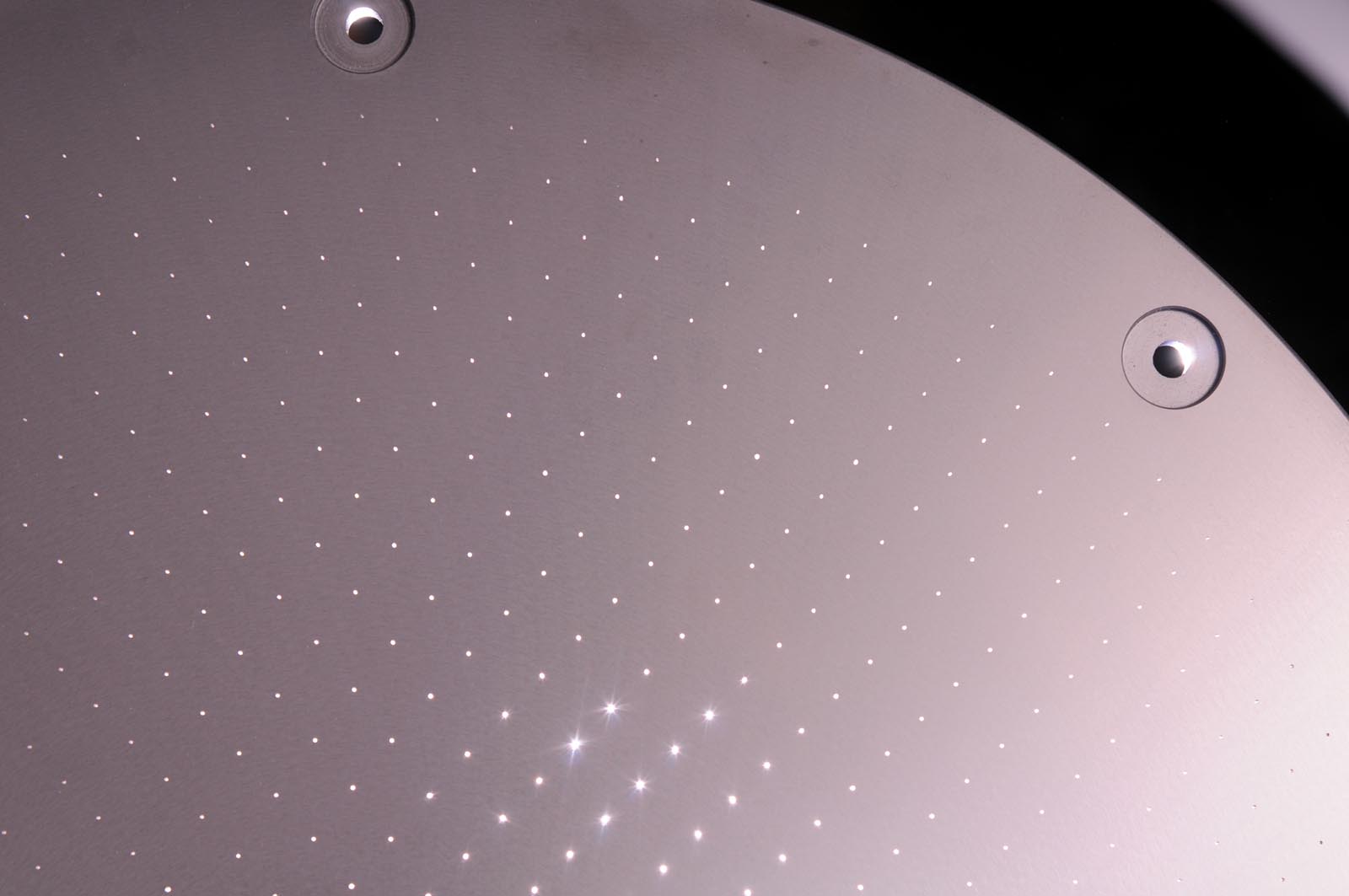

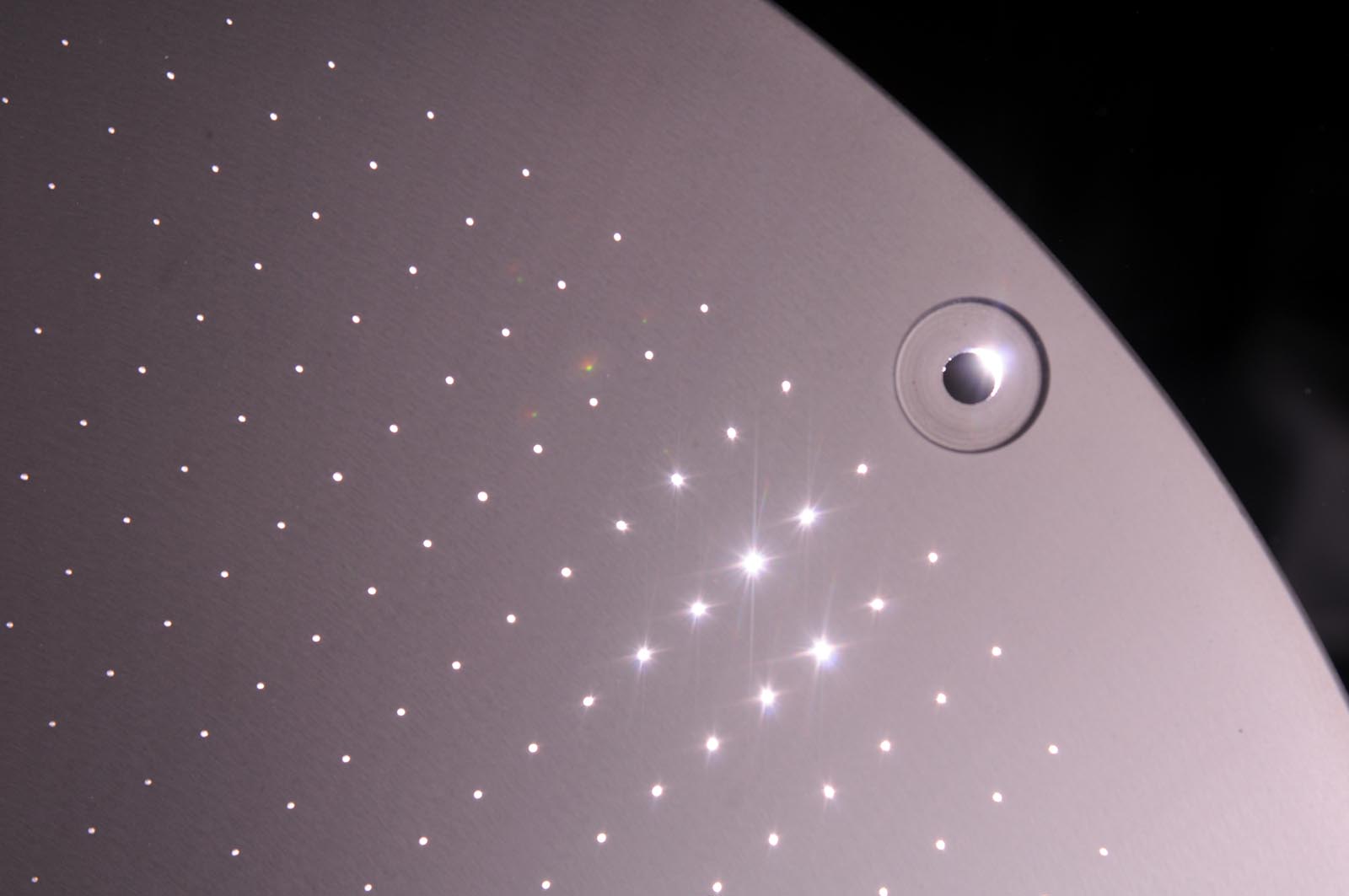

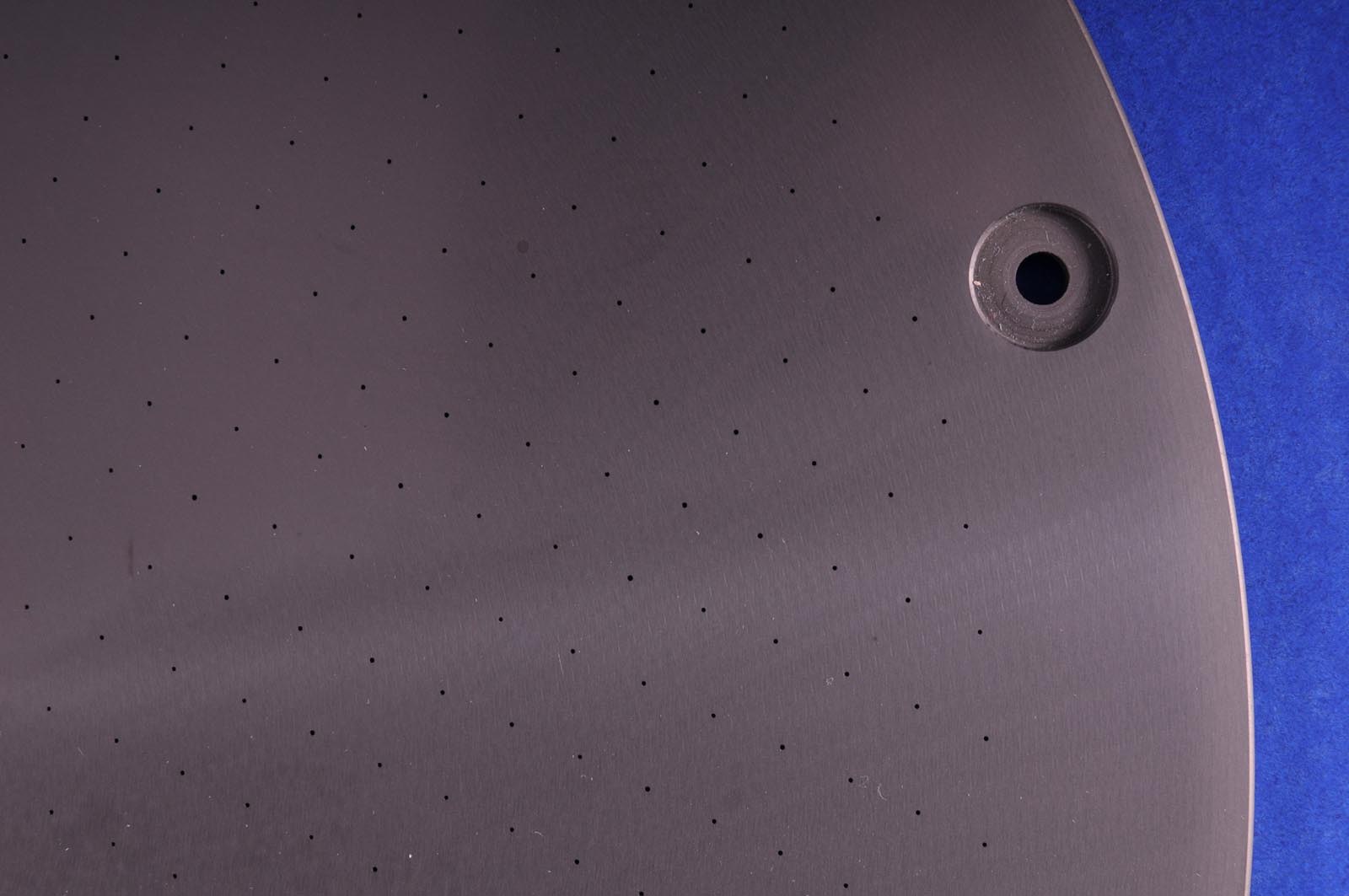

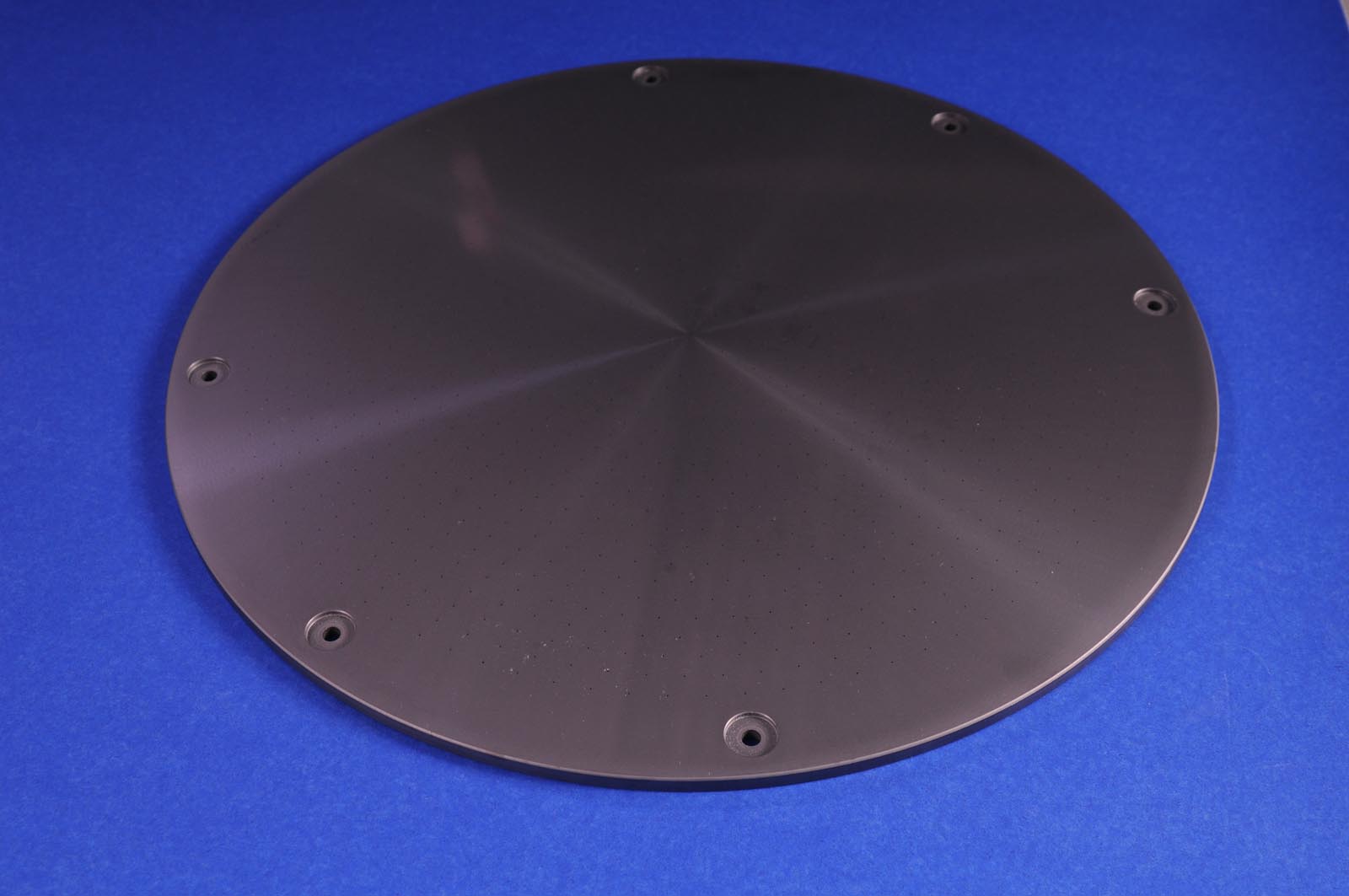

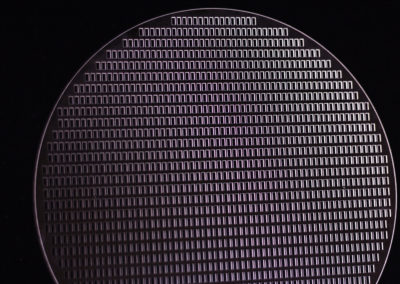

✓ Ultrasonically high aspect ratio precision features in 300 mm diameter components

✓ Materials include CVD Silicon Carbide, Alumina, Sapphire, Aluminum Nitride, Silicon, Silicon Nitride, Yttria, and many others.

Part types typically machined include:

Gas distribution plates, showerheads (electrodes)

Wafer chucks

Wafer Carriers

Machining limitations shouldn’t hold you back

Bullen offers unique capabilities beyond traditional machining

Our proprietary capabilities deliver viable solutions to complex engineering problems.

ULTRASONIC MACHINING

The world’s leading Ultrasonic Machining company, Bullen provides a superior solution to traditional machining when your design requires a feature or pattern in certain hard, brittle, & specialty materials.

Explore Ultrasonic Machining >

MICROLUCENT® MACHINING

Bullen uses unique laser technology to cut precise features in transparent materials. This proprietary technology lowers costs while improving the quality of cuts.

Explore Microlucent® Machining >

News

From Controls Engineer to Manufacturing Leader: How John’s Career Was Built on Grit, Growth, and Learning from the Hard Stuff Not every career path is straight—and John will be the first to tell you that’s a good thing. John started out like many of us—trying to pay for college, working a co-op job at […]