We Are Bullen Ultrasonics

Helping Technical Teams Bring Their Design To Life for Over Fifty Years

Ultrasonic Machining | Microlucent® Machining

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

Supporting Engineers with Cutting Edge Machining Tech

For 50 years, Bullen has remained a globally recognized leader in ultrasonic machining of high-quality components used in semiconductors, MEMS, transportation, defense & aerospace, medical & life sciences industries. In 2021, we began offering MicroLucent® machining, unique laser technology to cut precise features in transparent materials.

What started as a small group of engineers repairing ultrasonic equipment in their garage has turned into a “machining powerhouse” and globally recognized industry leader. Despite our growth, we remain just as committed to our employees and our customers as we were on Day One.

Looking for an answer to a specific question?

Check out our FAQ.

VISION

Transforming opportunities into realities…

Customer: Through innovation, bringing designs to life

Co-workers: Through culture, improving quality of life

Community: Through partnerships, shaping an empowered future

MISSION

We deliver precision machining solutions in advanced ceramics through…

Being a Collaborative Partner

Utilizing Technology for Unparalleled Value

Leading the Industry with Reliable Processes

Leveraging Innovation

Empowering People to Achieve Their Full Potential

Navigating Complex Requirements Through Teamwork

Values

We are an extended family in the marketplace, passionately committed to…

Excellence: Bringing our best to all we do

Humility: Accurately estimating our capabilities and seeking to learn more

Integrity: Keeping our word in every circumstance

Teamwork: Accomplishing more through healthy work relationships

Our Equipment and Technology

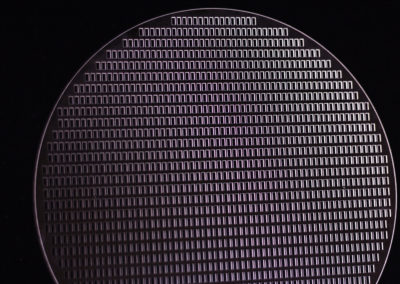

Our unique and unconventional machining technology has enabled high-tech companies to solve many of their most challenging problems for decades. We provide precision machining services for brittle materials such as glass and advanced ceramics. Our equipment uses ultrasonic technology to create a limitless number of feature shapes, including round, square, and odd-shaped thru-holes and cavities of varying depths. We build our custom equipment and tools with an internal metal CNC machining shop. By designing and developing our machines, we can remain fully vertically integrated for ultrasonic machining services, decreasing cost and allowing unmatched quality control for our customers.

Our associations

News

From Controls Engineer to Manufacturing Leader: How John’s Career Was Built on Grit, Growth, and Learning from the Hard Stuff Not every career path is straight—and John will be the first to tell you that’s a good thing. John started out like many of us—trying to pay for college, working a co-op job at […]