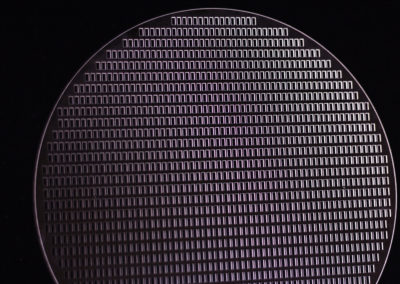

MEMS Technical Glass

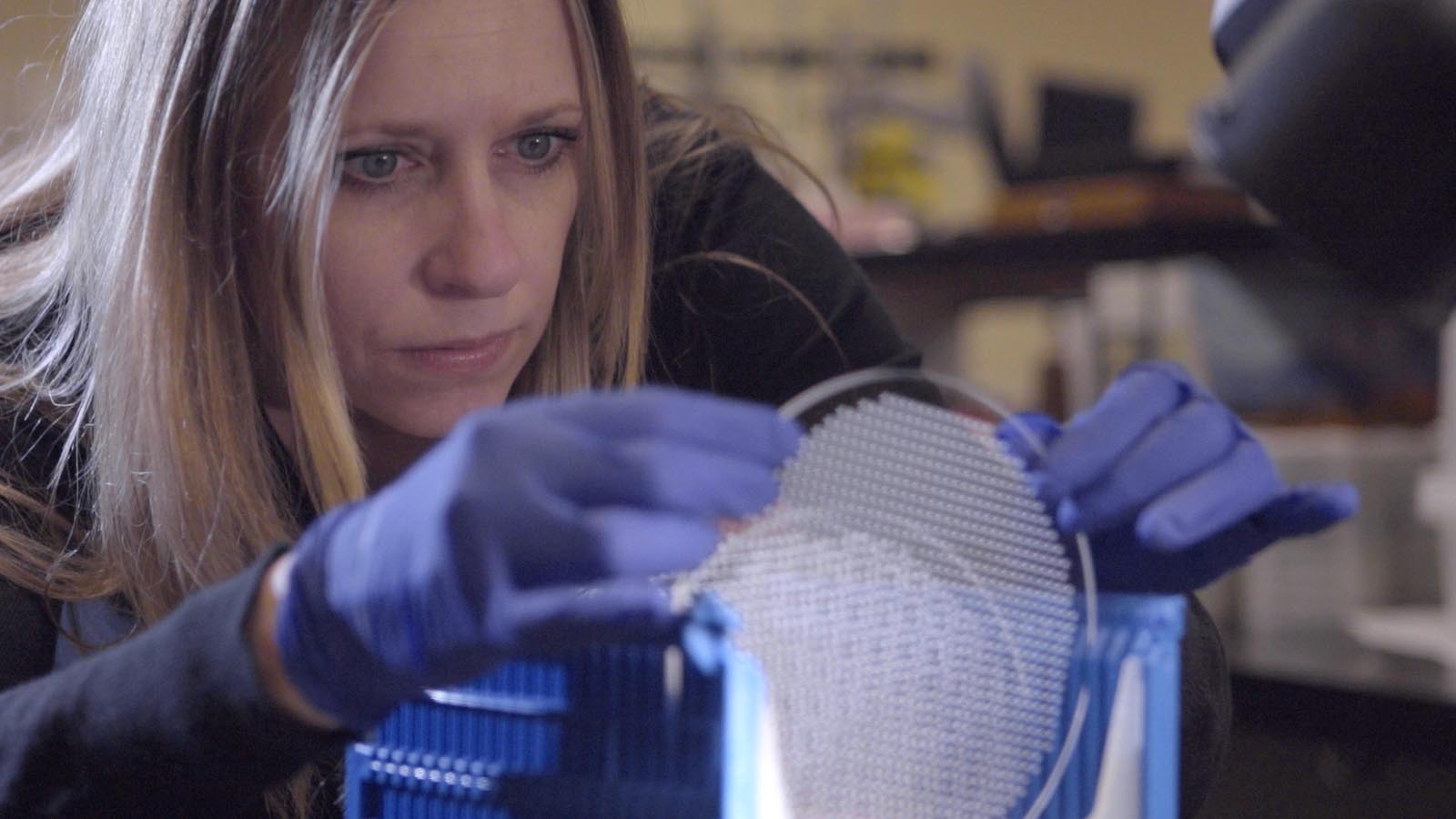

Microelectromechanical (MEMS) and microsystem developers worldwide trust Bullen to provide high-performance MEMS glass wafers and substrates for their prototype and production processing.

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

You’ve perfected the design – don’t compromise it.

Considering Traditional Machining for your MEMS Production?

Know what you’re getting Into:

Conventional Machining

(LASER/EDM)

Limited Number and Selection of Features, Shapes, and Sizes

Time-Consuming Process

Potential Heat-Affected and Subsurface Damage

Possible Negative Impact End-Use

BULLEN ULTRASONIC MACHINING

Lower Net Cost

Higher Production Yield

No Post-Processing Steps Required

Greater Design Reliability & Quality

More Feature Sizes Possible

bullen technical glass capabilities

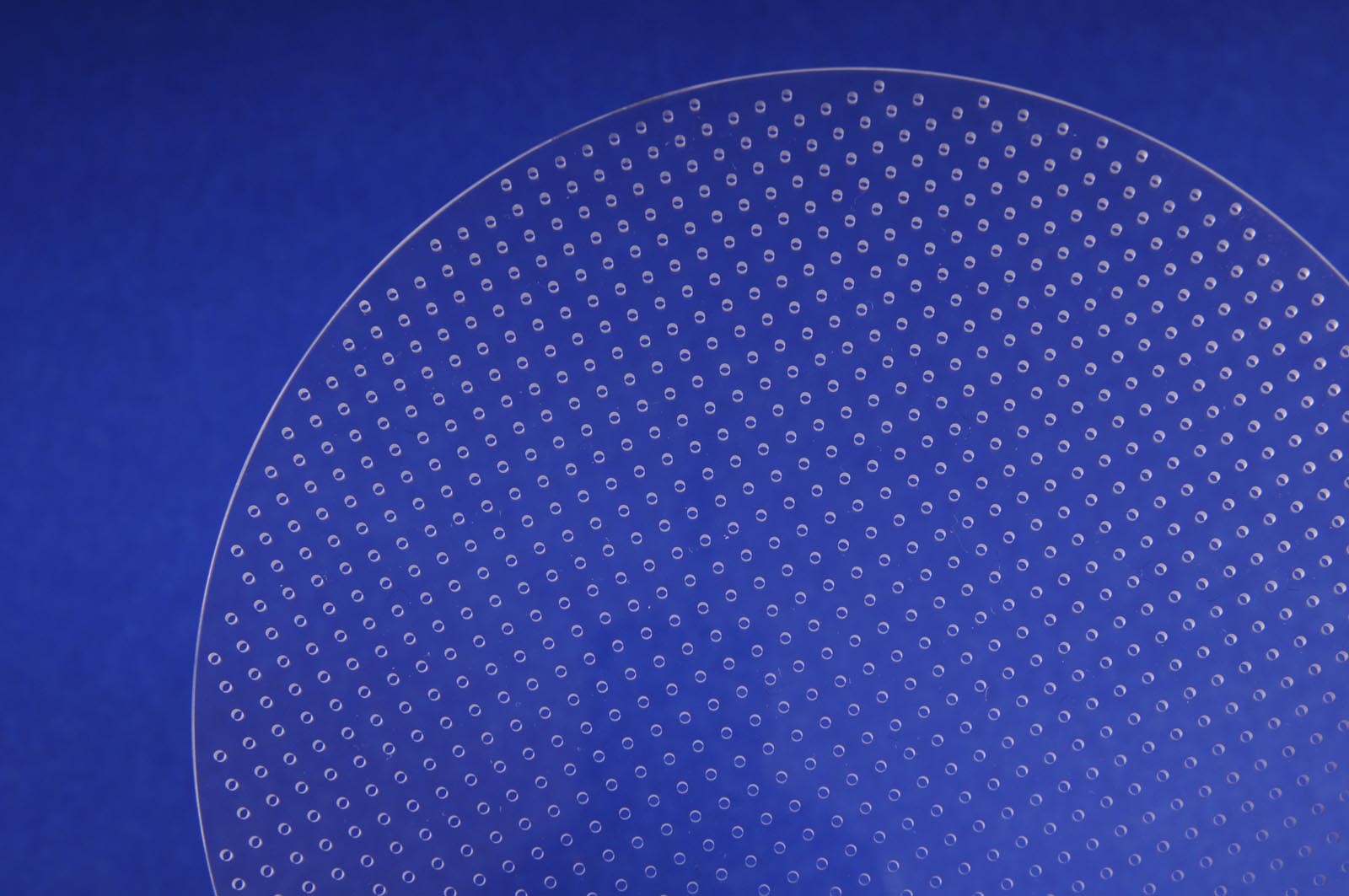

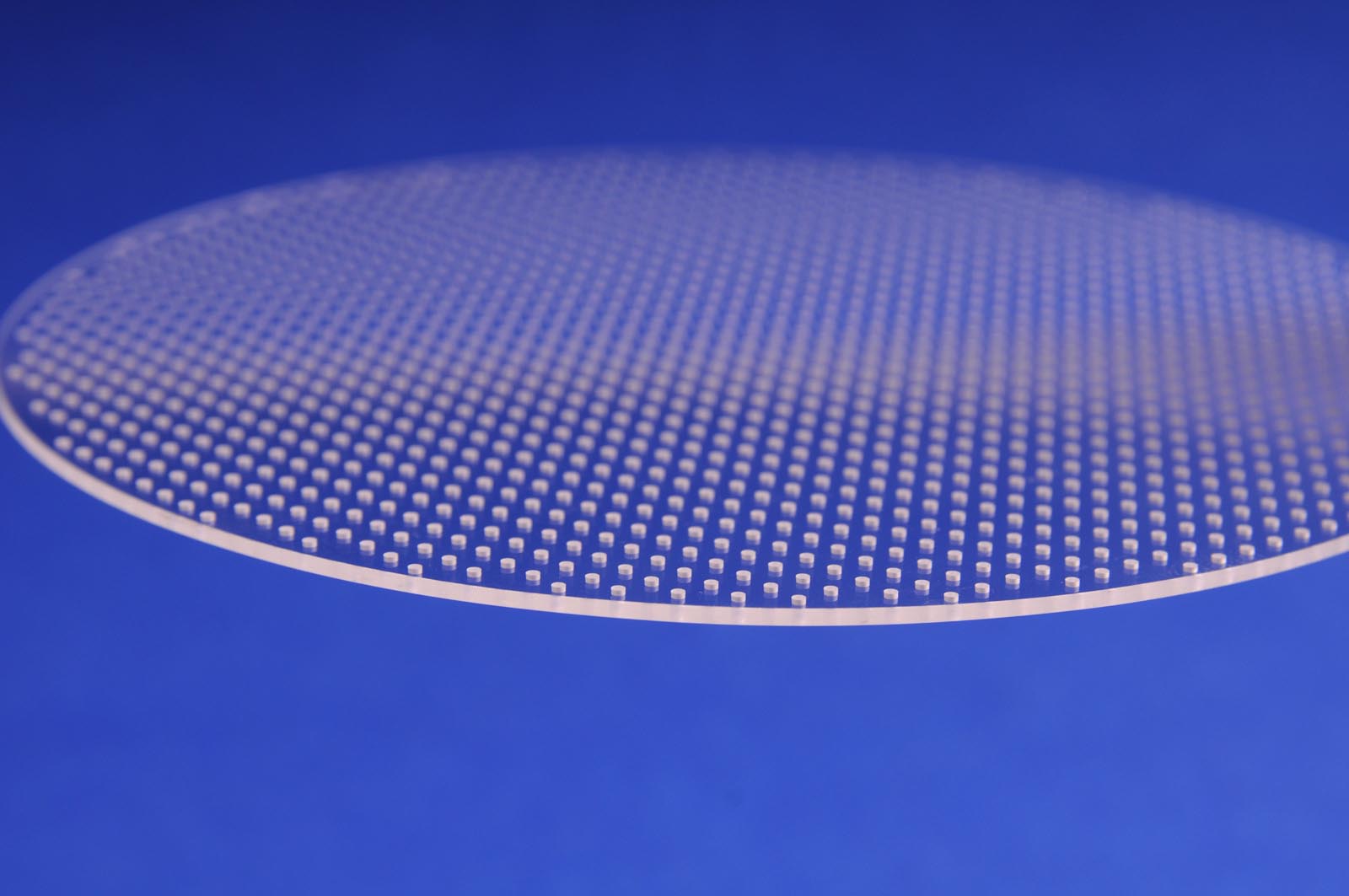

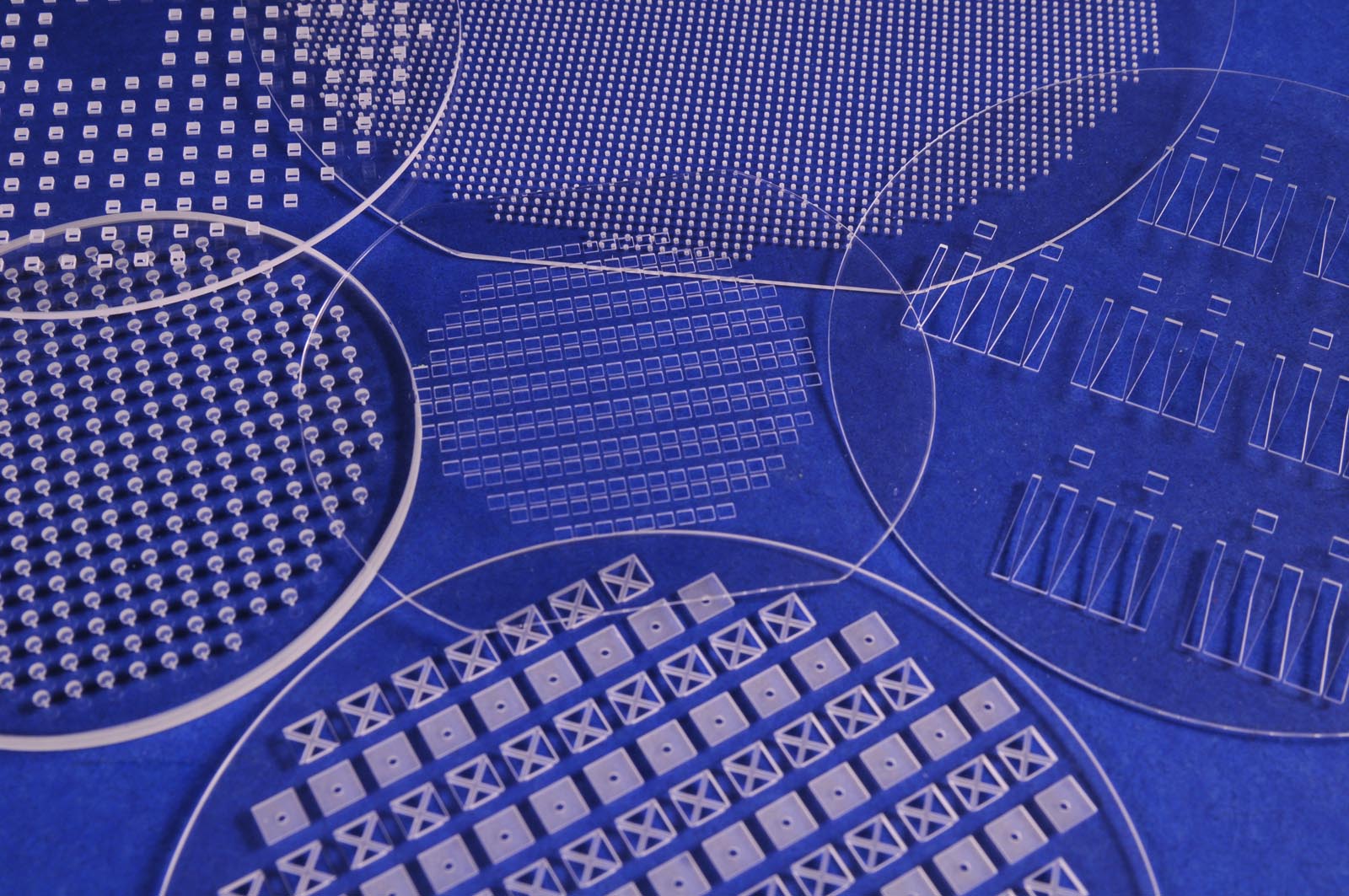

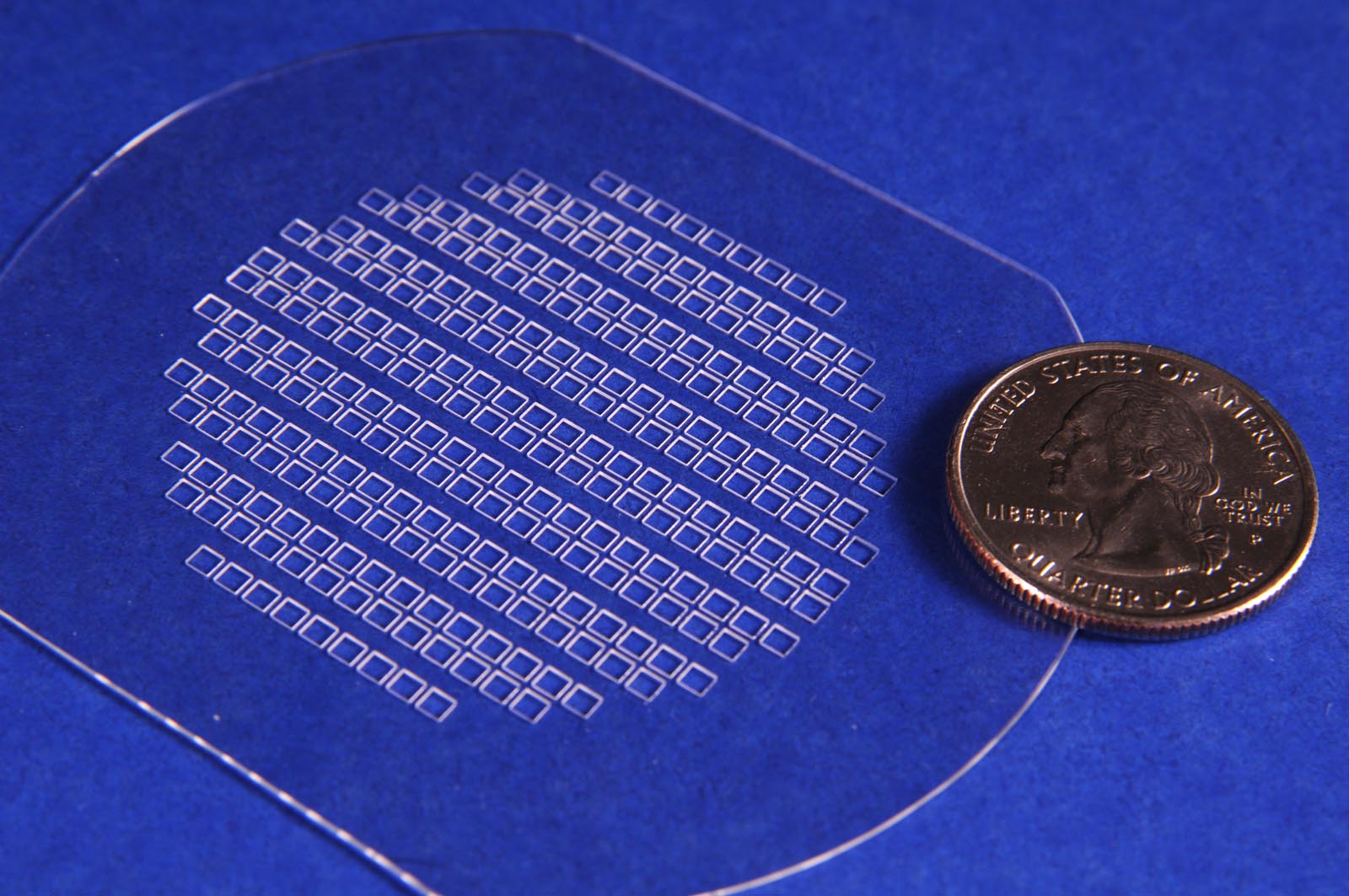

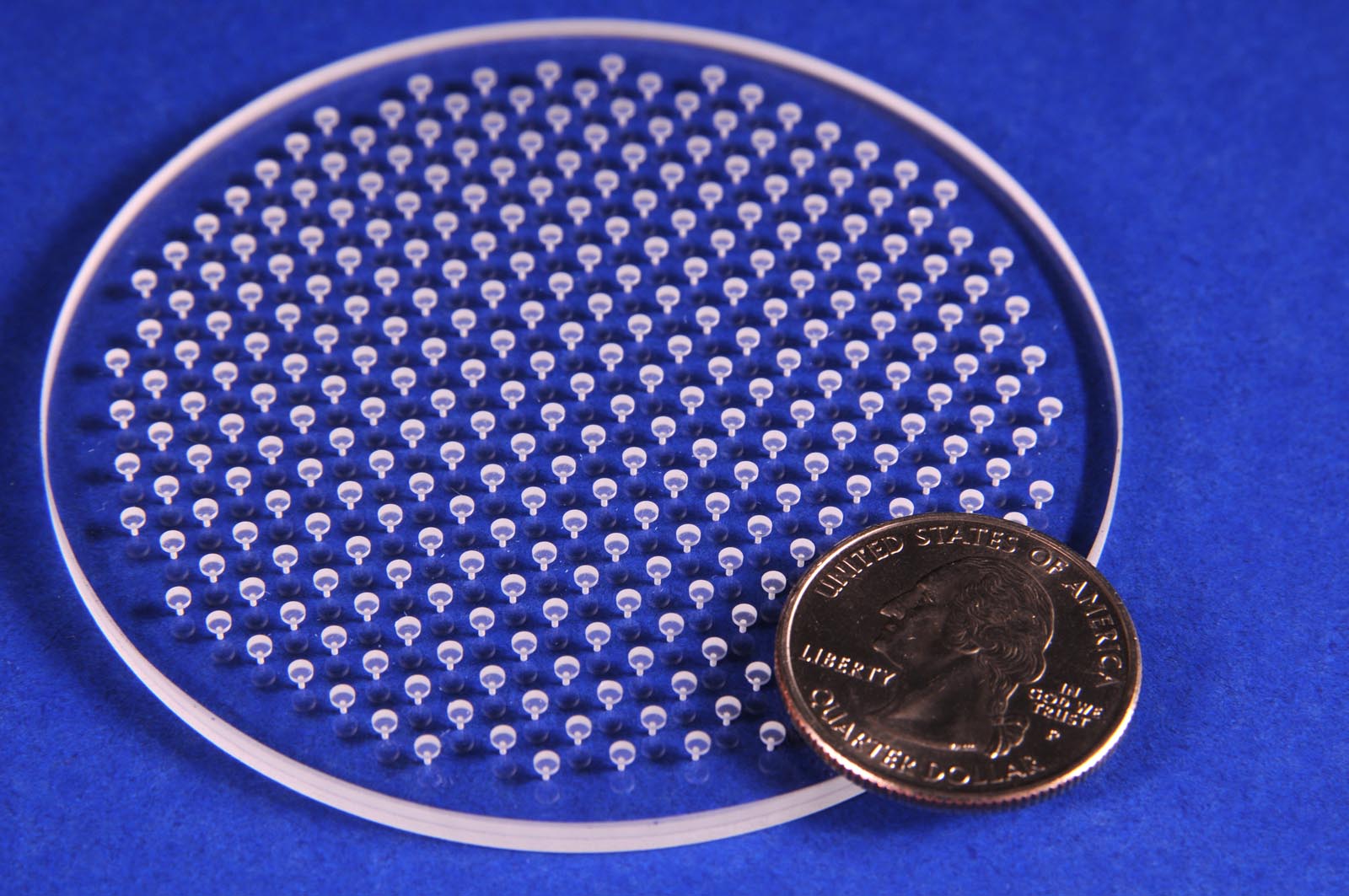

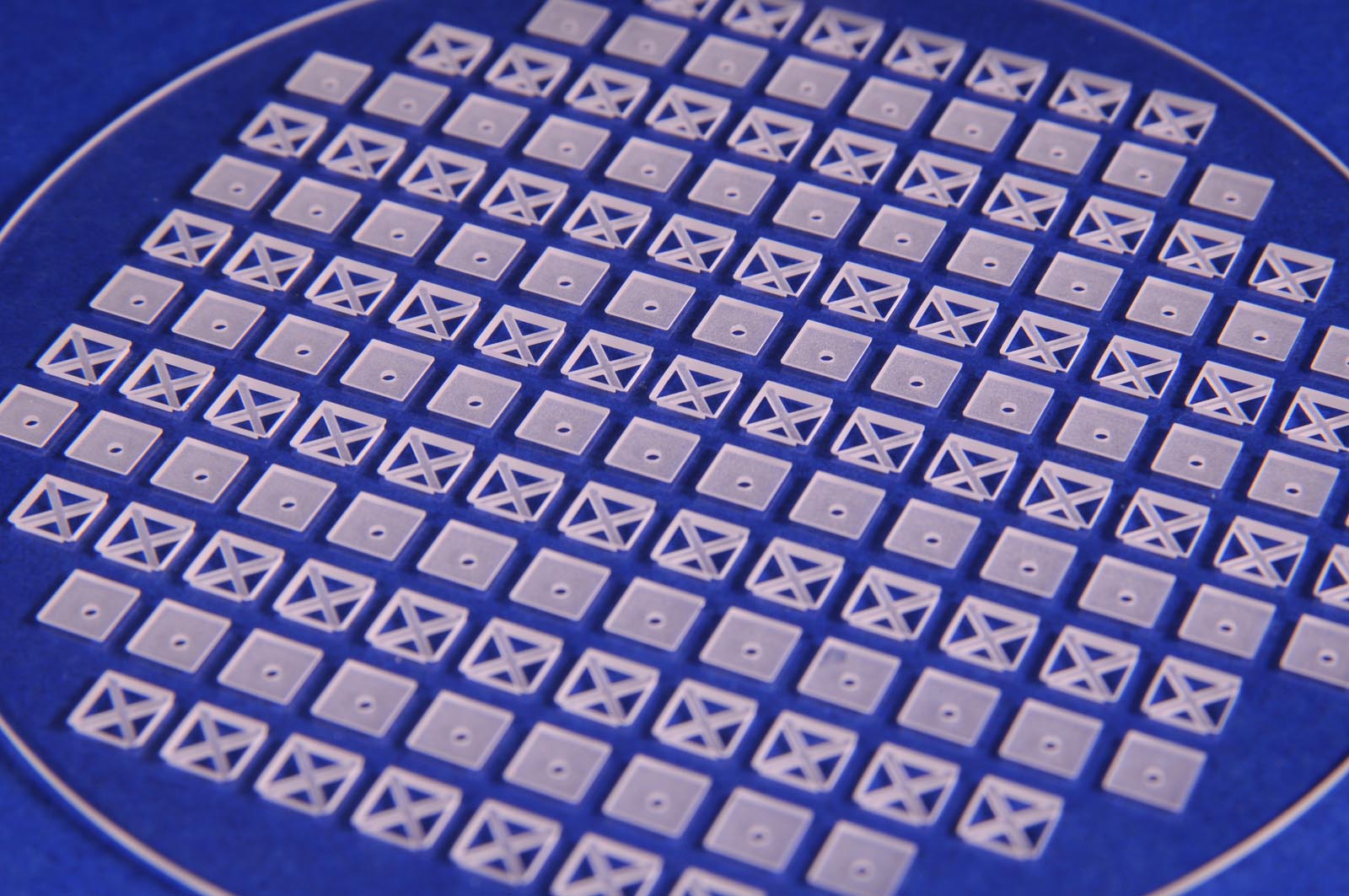

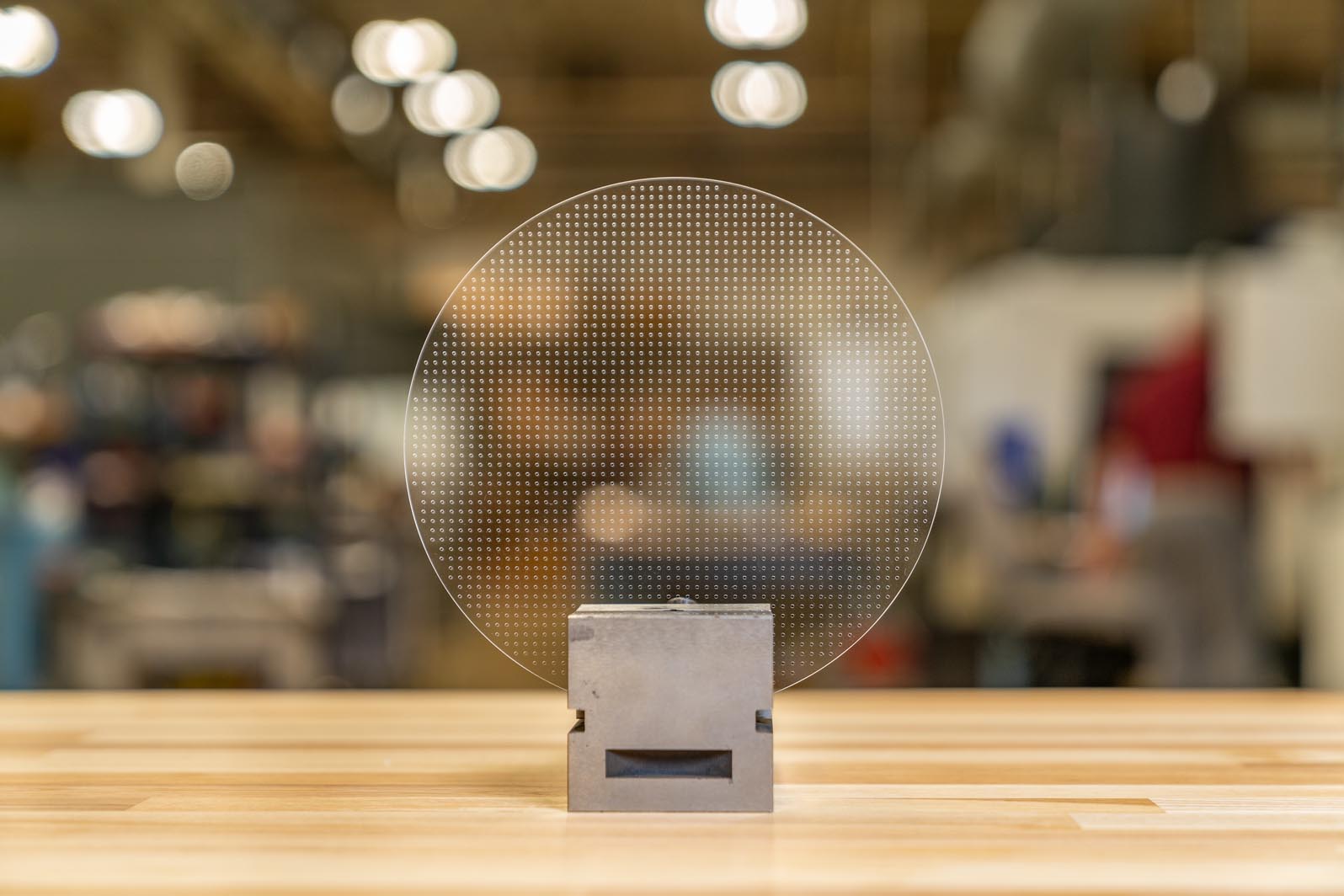

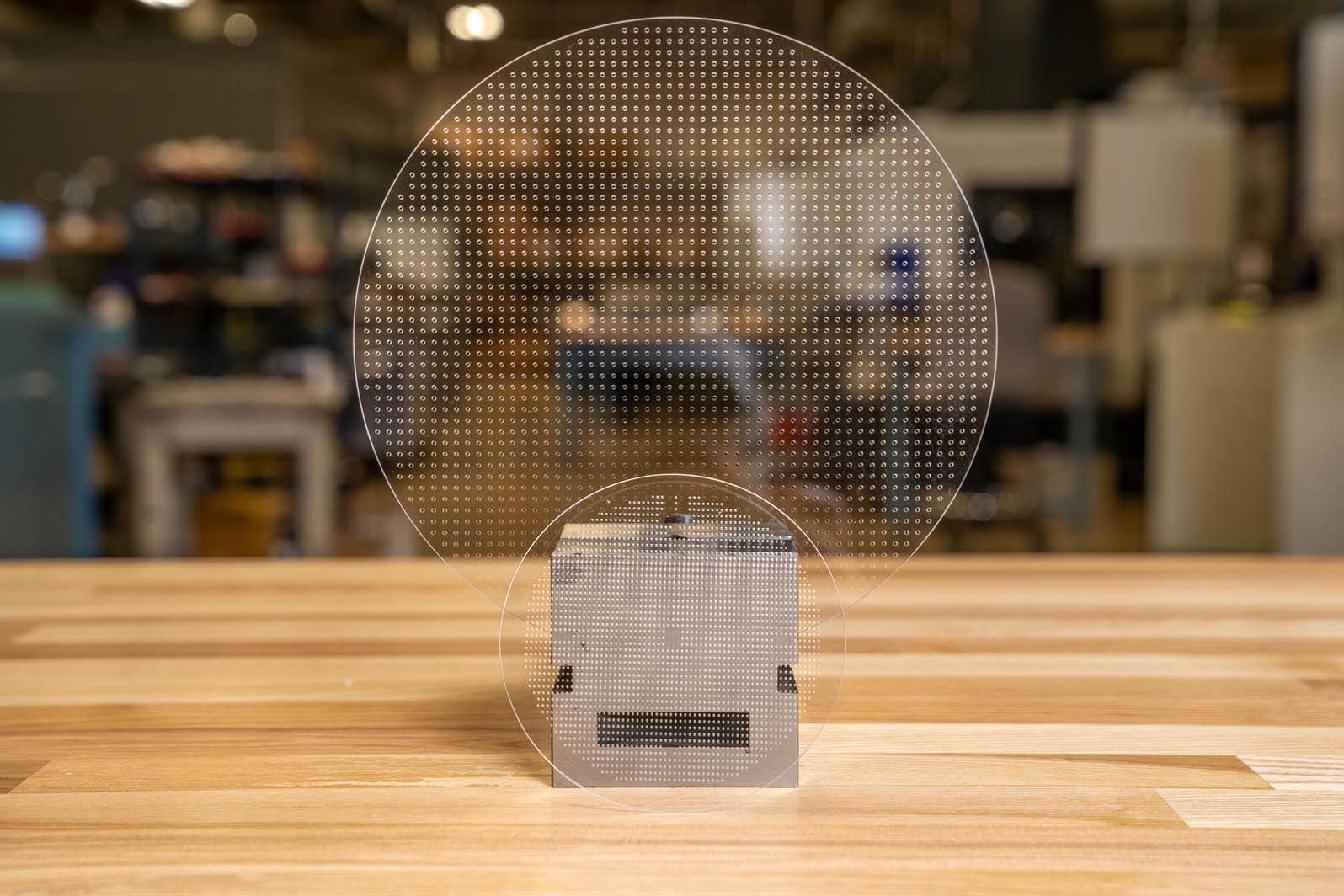

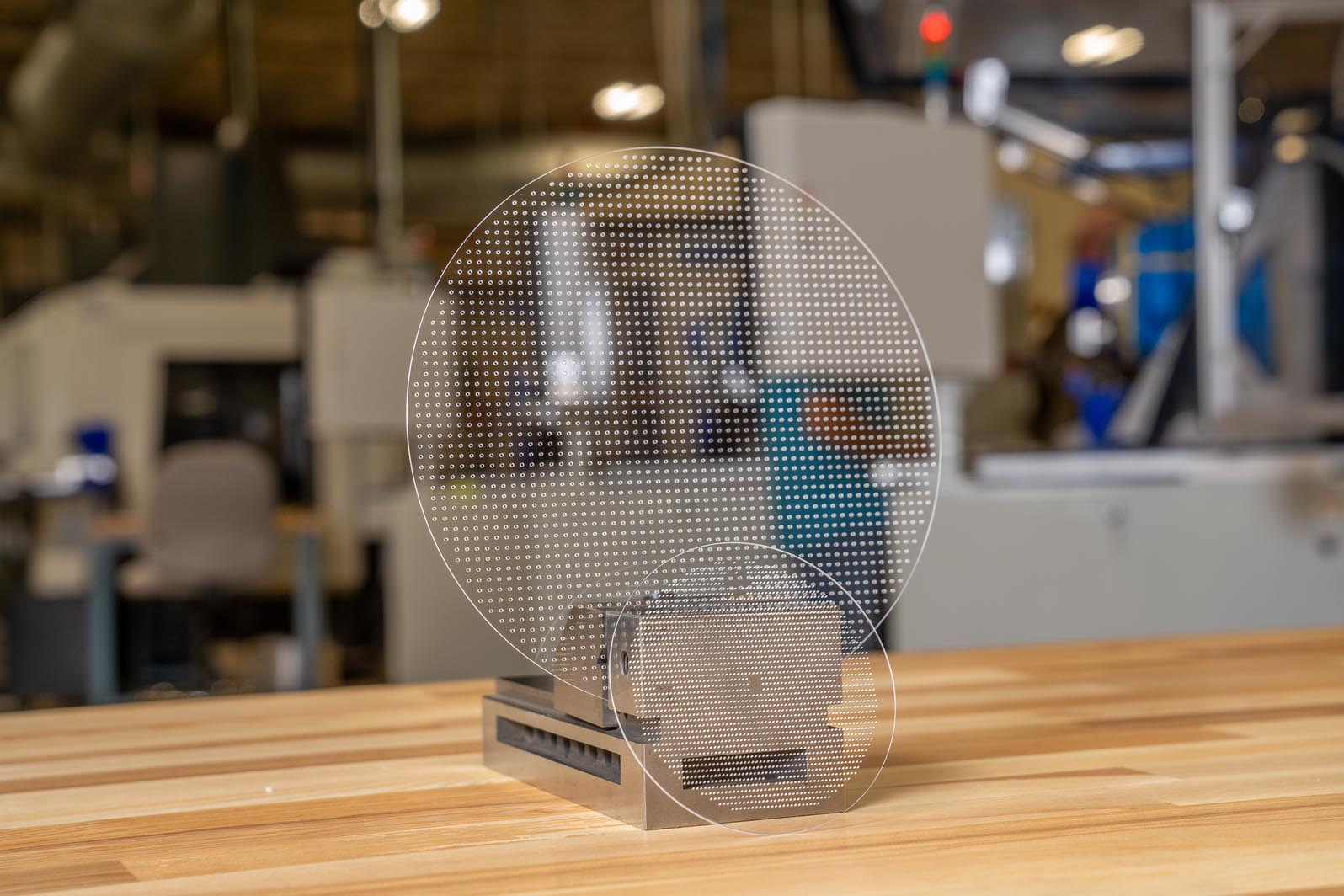

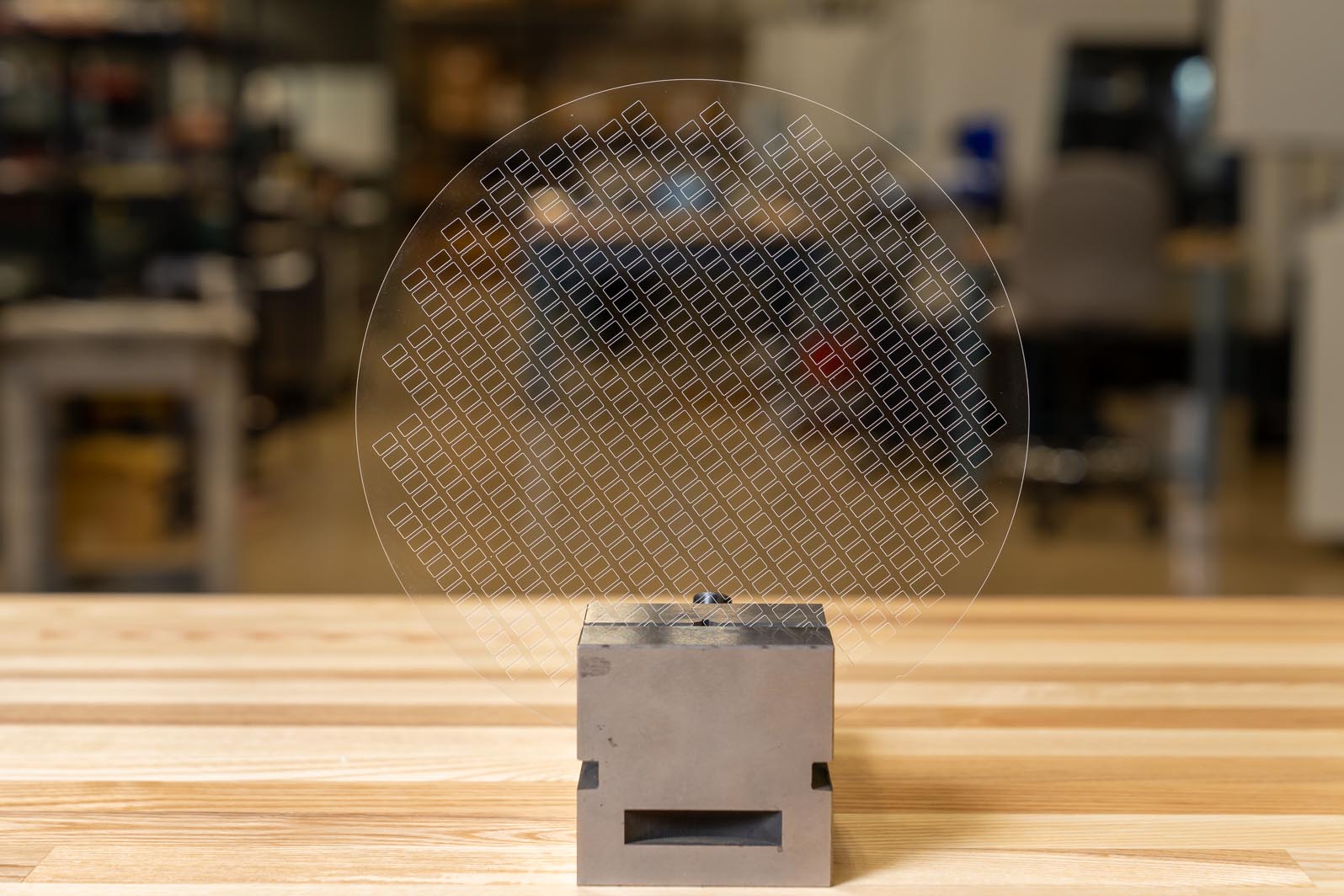

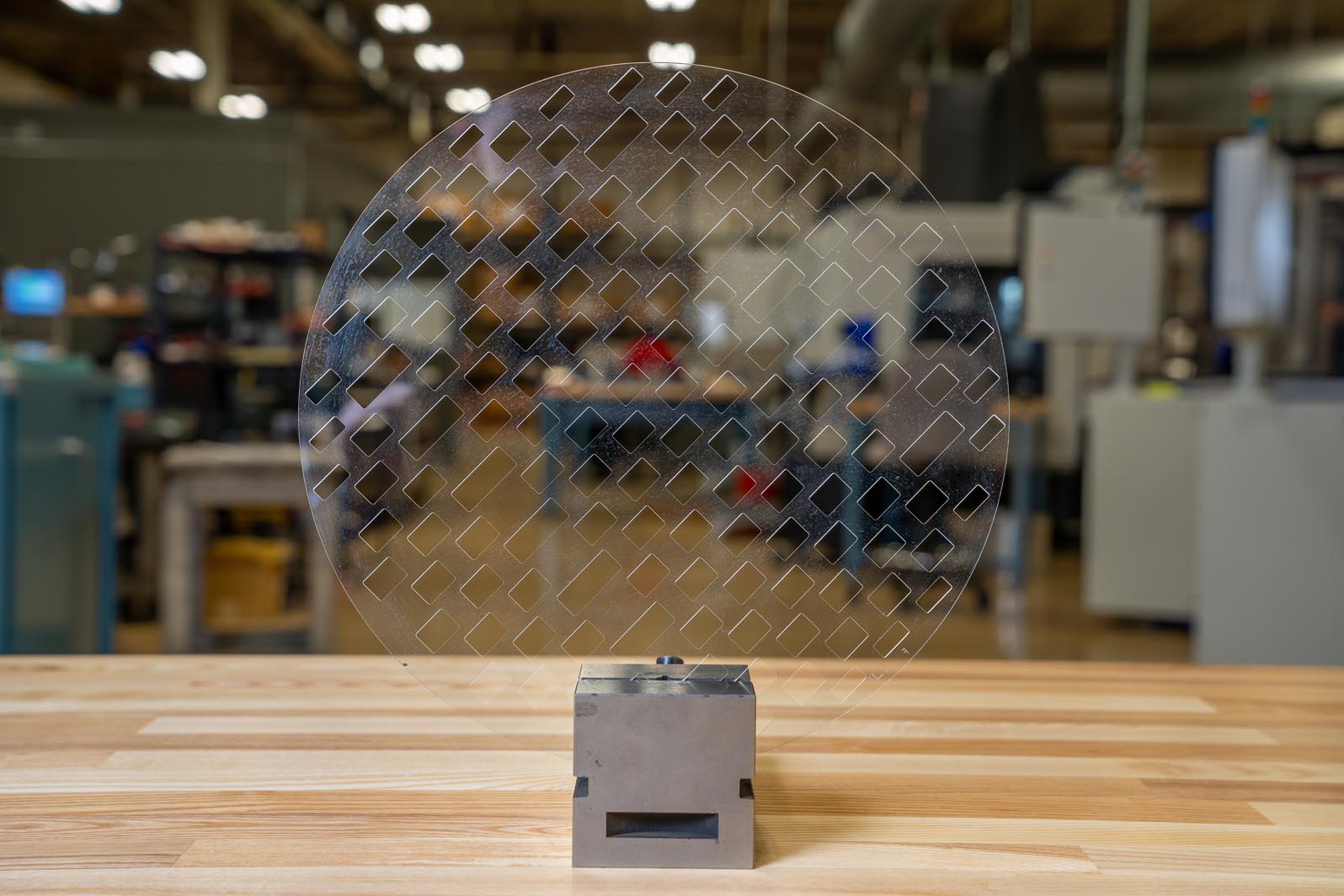

✓ ULTRASONICALLY HIGH ASPECT RATIO PRECISION FEATURES IN 300 MM DIAMETER COMPONENTS

✓ Tapered or straight-walled round, square, and odd-shaped vias and cavities

APPLICATIONS

Bullen structured glass wafers and substrates are used in a wide range of MEMS applications, including:

Pressure Sensors

Inertial Measurement Units

DNA Analysis

Implantable Sensors

you deserve a better option

We’ll work with you to determine which non-traditional process is right for your design.

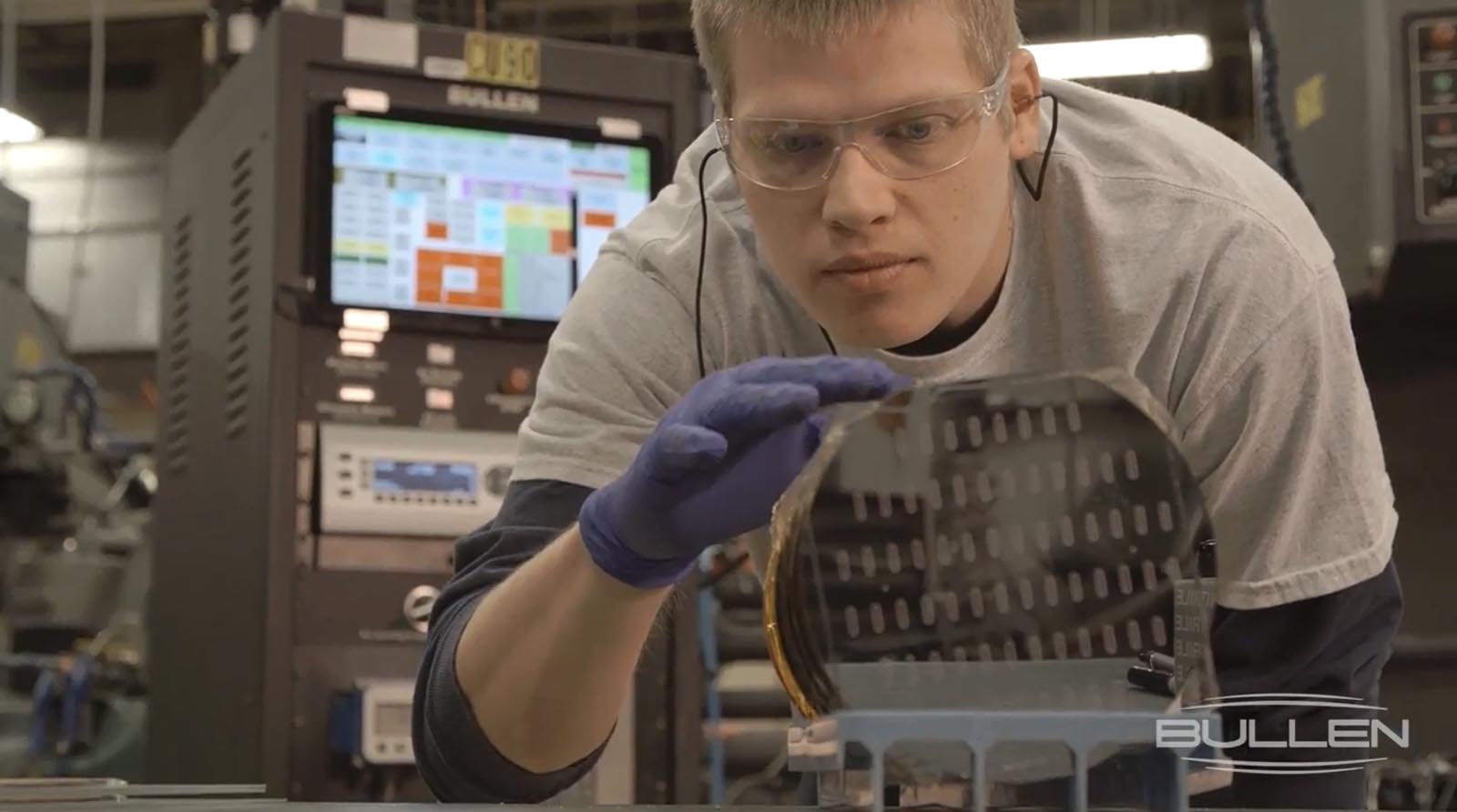

ULTRASONIC MACHINING

The world’s leading Ultrasonic Machining company, Bullen provides a superior solution to traditional machining when your design requires a feature or pattern in certain hard, brittle, & specialty materials.

Explore Ultrasonic Machining >

MICROLUCENT® MACHINING

Bullen uses unique laser technology to cut precise features in transparent materials. This proprietary technology lowers costs while improving the quality of cuts.

Explore Microlucent® Machining >

Bullen glass wafers set the standard for quality and precision, allowing you to focus on your process and design rather than your supplier parts’ quality.

News

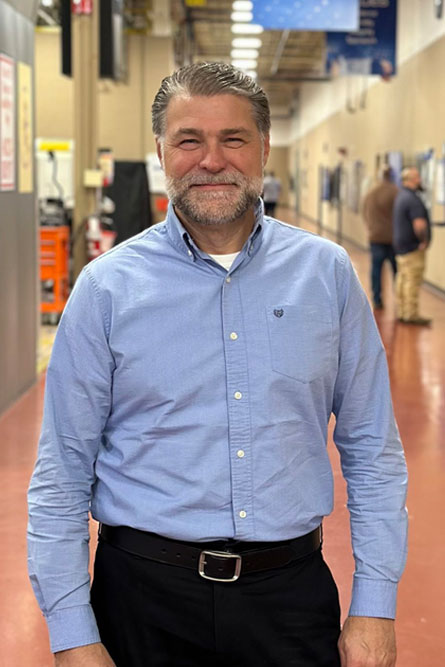

From Controls Engineer to Manufacturing Leader: How John’s Career Was Built on Grit, Growth, and Learning from the Hard Stuff Not every career path is straight—and John will be the first to tell you that’s a good thing. John started out like many of us—trying to pay for college, working a co-op job at […]