Semiconductor Ceramics

Semiconductor equipment manufacturers, fabricators, and ceramic material manufacturers rely on Bullen for precision machining & Drilling of critical ceramic components for semiconductor process equipment.

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

You’ve Perfected the Design – Don’t Compromise it

Bullen’s extensive knowledge in the machining of glass and ceramics, combined with unique ultrasonic machining capabilities, enables us to provide custom, high-quality, cost-effective solutions that meet the strict requirements of the semiconductor industry.

Conventional Machining

(Laser, EDM)

Higher Part Costs

Lower Process Yield

Common Processing Defects

Subsurface Damage

Longer Process

Bullen Ultrasonic Machining

Reduced Part Costs

Higher Process Yield

Greater Design Reliability & Quality

Little To No Subsurface Damage

Reduced Downtime

We Believe You Deserve a Better Solution for your semiconductor component

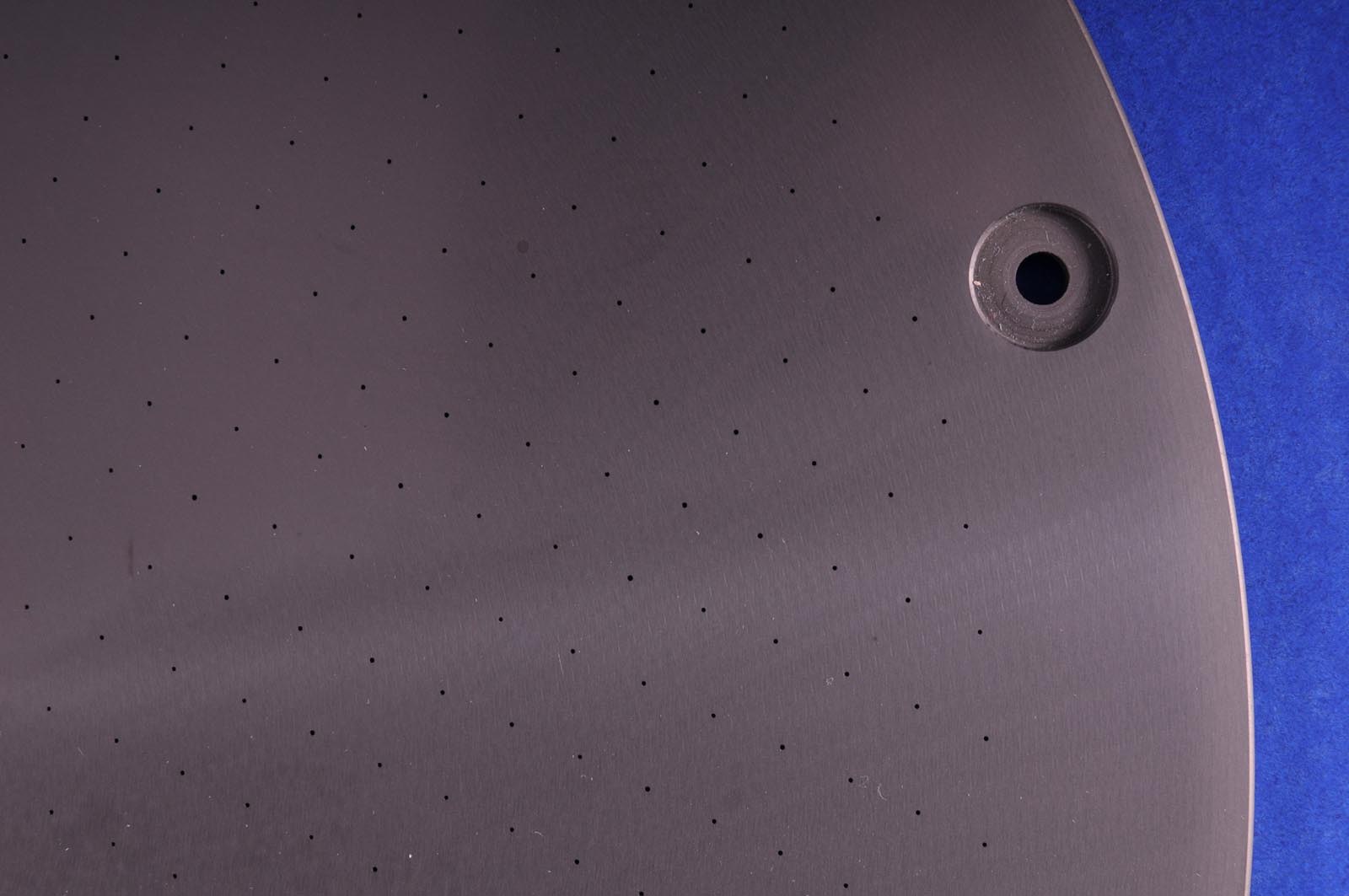

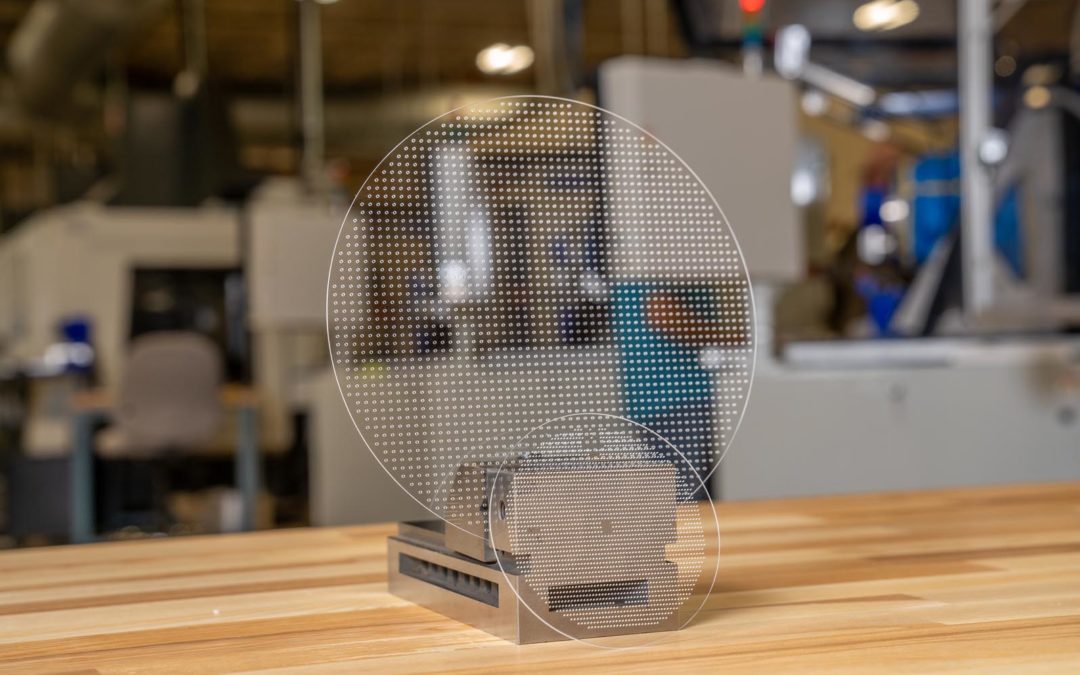

Bullen’s Ultrasonic Machining process is a non-thermal method, creating no HAZ (Heat Affected Zone) and little to no subsurface damage. As a result, no post-machining polishing is needed to relieve residual stress and slag caused by laser machining or EDM. That means a faster and more cost-effective process for your team.

Preserve Material Reliability

The substrate material’s chemical and physical properties remain unchanged.

Expand Design Possibilities

Implement feature sizes not possible with laser machining on thicker substrates.

Optimize Production

Eliminate inefficiencies that slow down production and increase the cost.

BULLEN Semiconductor Capabilities

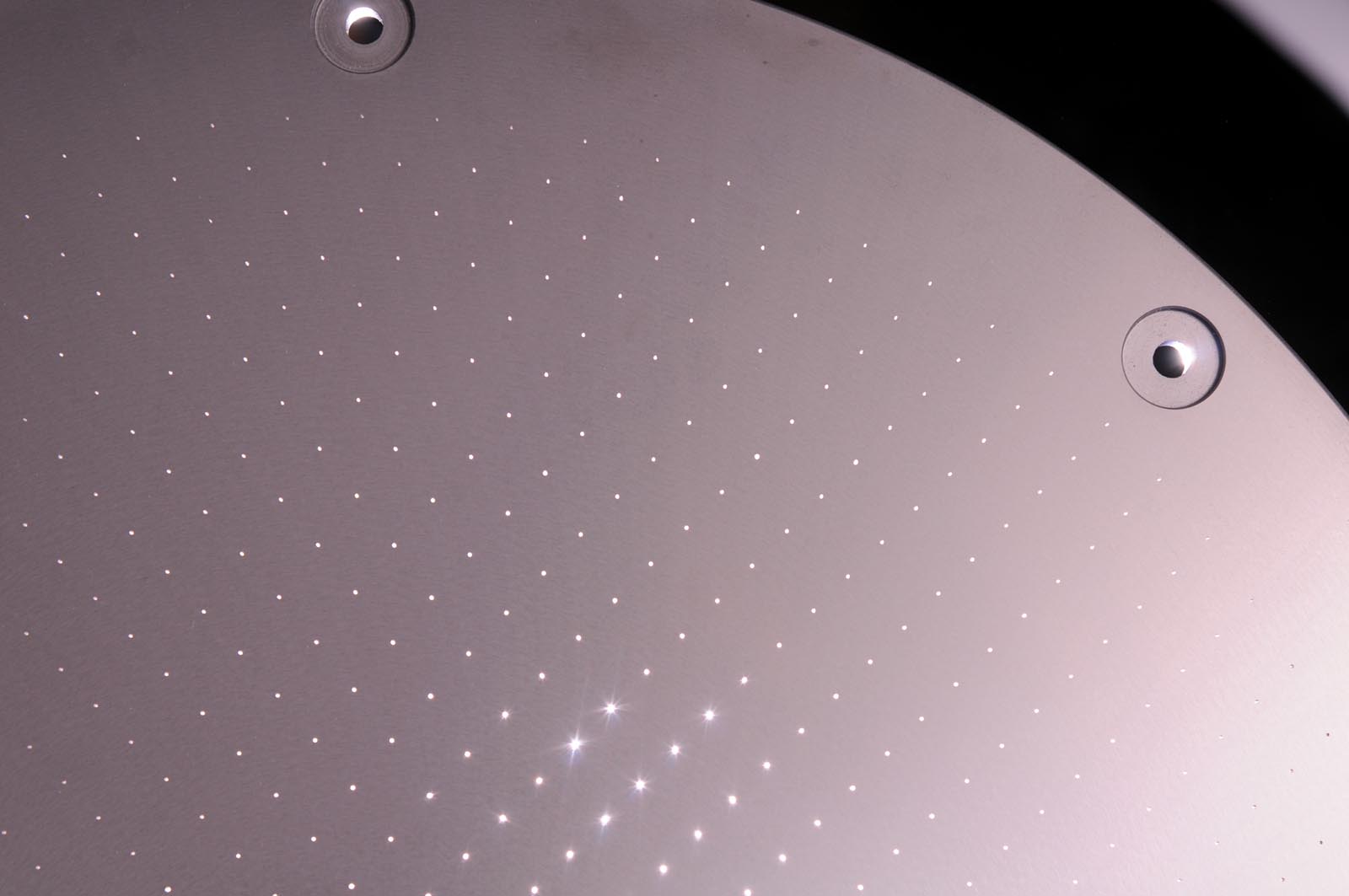

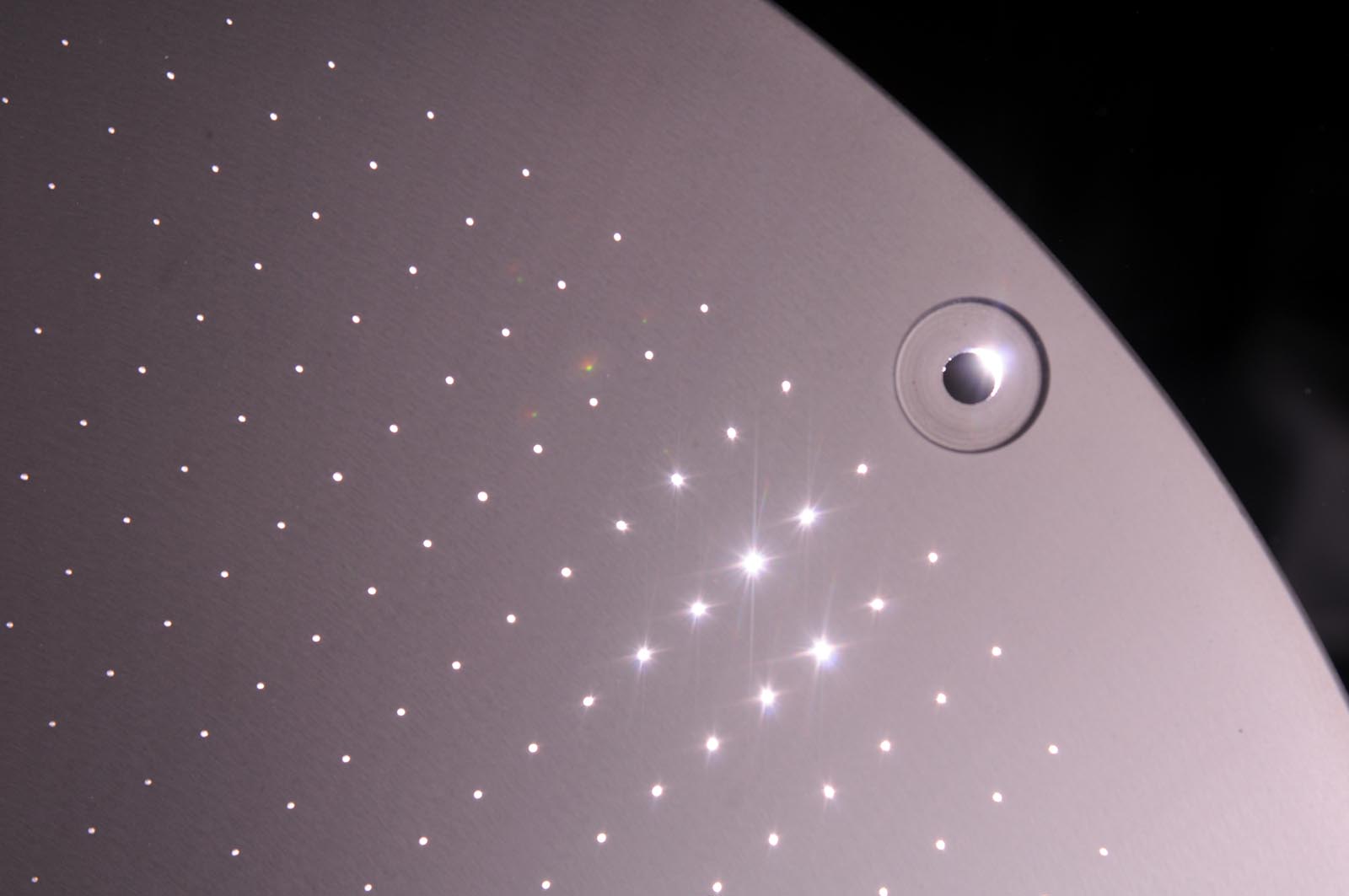

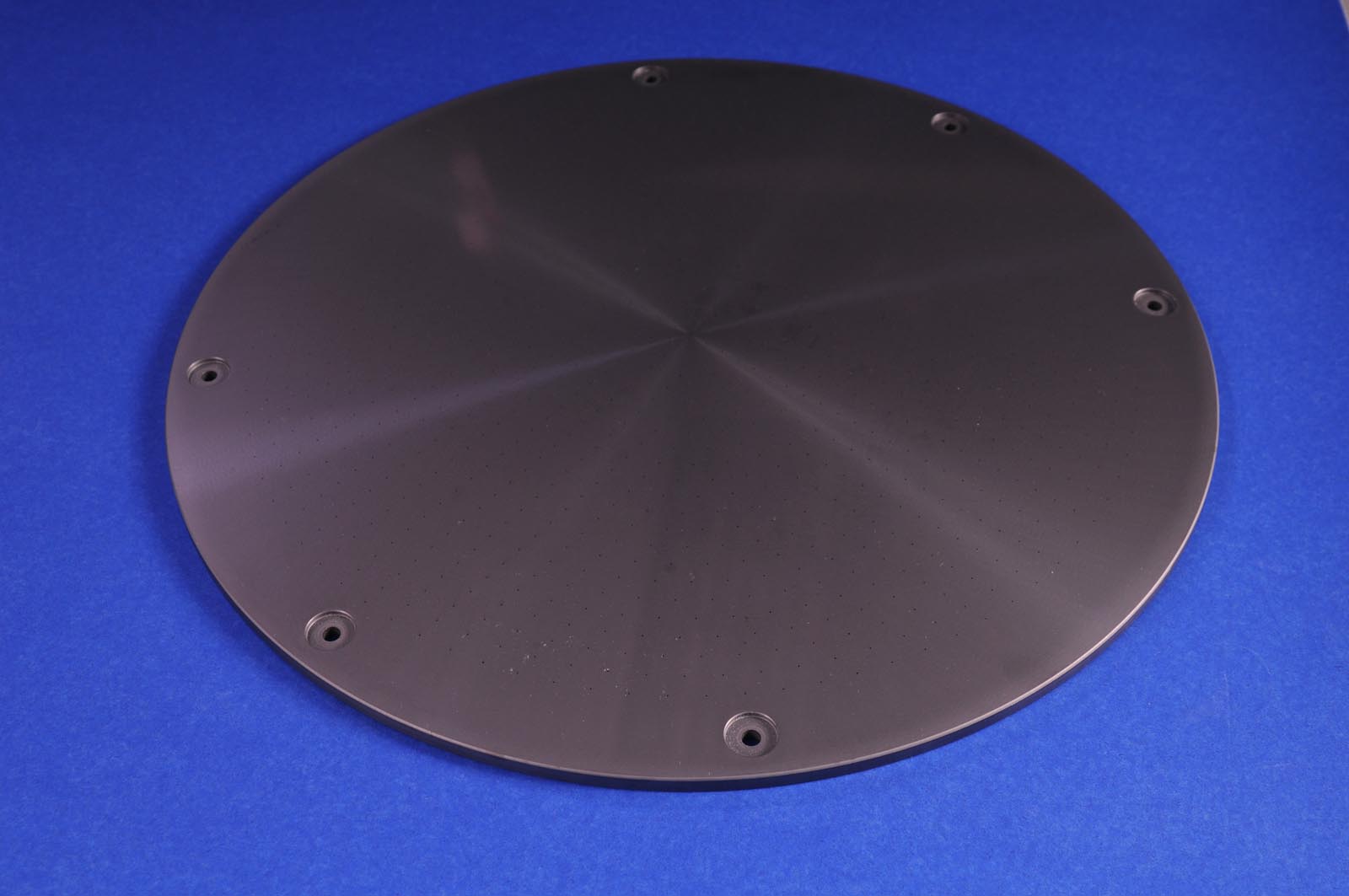

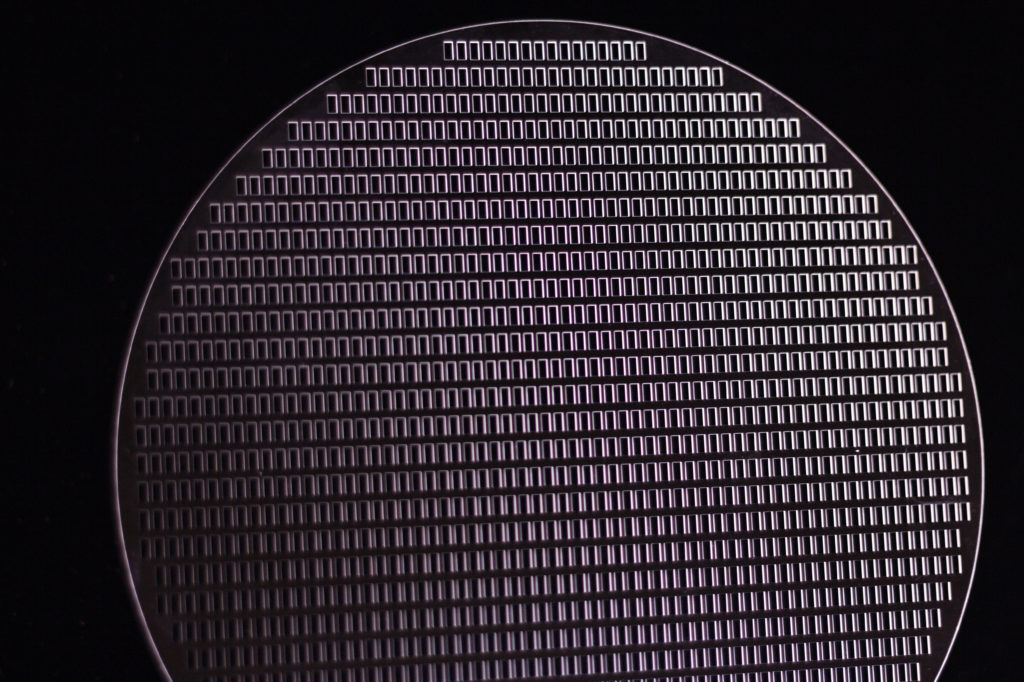

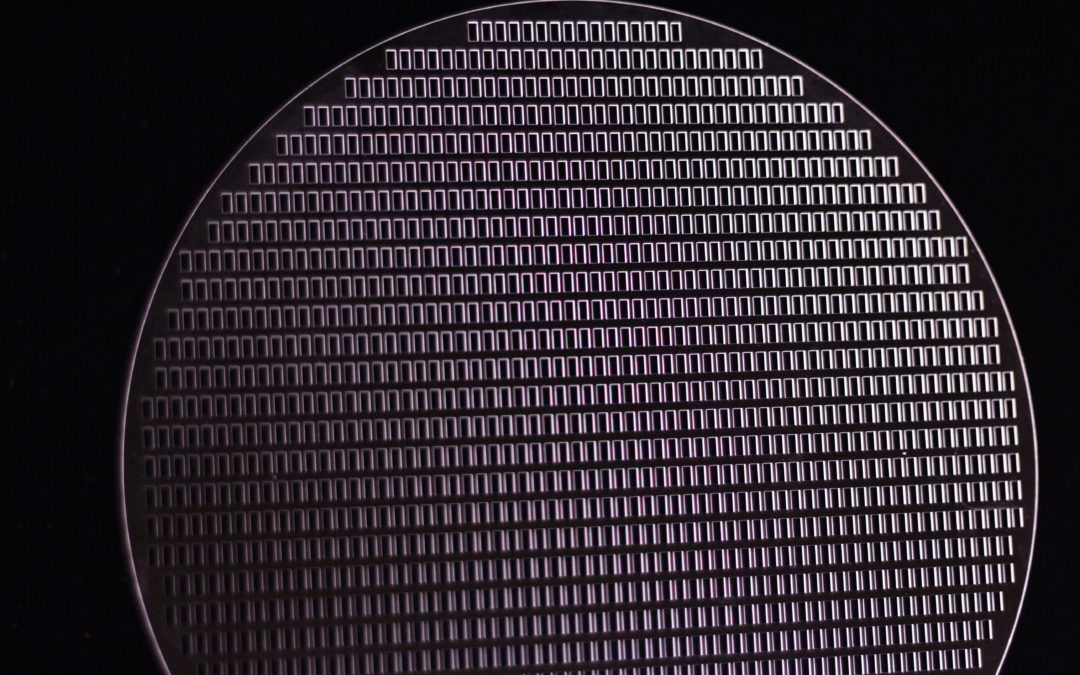

✓ Ultrasonically high aspect ratio precision features in 300 mm diameter components

✓ Materials include CVD Silicon Carbide, Alumina, Sapphire, Aluminum Nitride, Silicon, Silicon Nitride, Yttria, and many others.

Part types typically machined include:

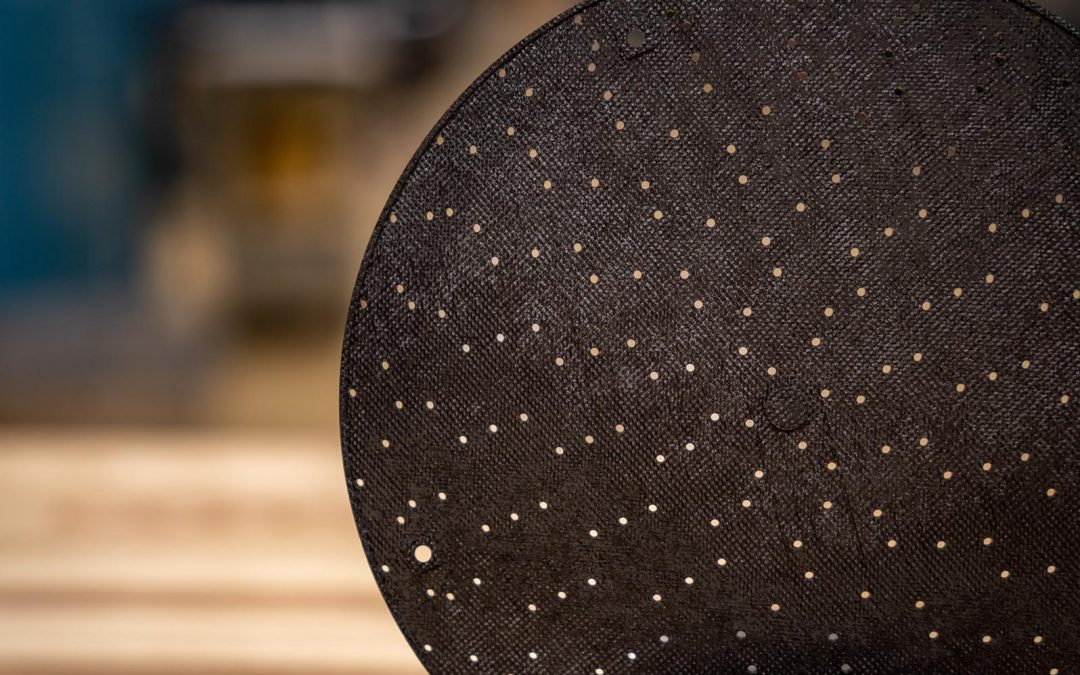

Gas distribution plates, showerheads (electrodes)

Wafer chucks

Wafer Carriers

Your Trusted Partner Advanced Ceramics

At Bullen, we don’t just drill your part – we begin with final production in mind. Our dedicated team of engineers will:

Consider your unique needs.

Seek ways to drive down costs and increase efficiencies.

Build custom machines and tools to mass-produce your part if needed.

What is Ultrasonic Machining?

Ultrasonic machining is a loose abrasive machining process in which the mirror image of a shaped tool can be created in hard, brittle materials. Material removal begins with a vibrating tool. The vibration propels particles at accelerations in excess of 25,000 g’s. These dynamic particles collide with and grind the workpiece on a micro-level.

Learn More About Ultrasonic Machining >

News

MicroLucent® A few years ago, Bullen faced a problem. While we pride ourselves in our excellent service and quality, our customers were still searching for higher-quality machining at a fraction of the cost. To top that off, new markets were emerging that ultrasonic machining just wouldn’t cut it for. Literally. So how do you machine […]