ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

BRING YOUR DESIGN TO LIFE

Bullen matches the appropriate machining technology, methods, and materials to create solutions to your most difficult challenges – no matter your industry.

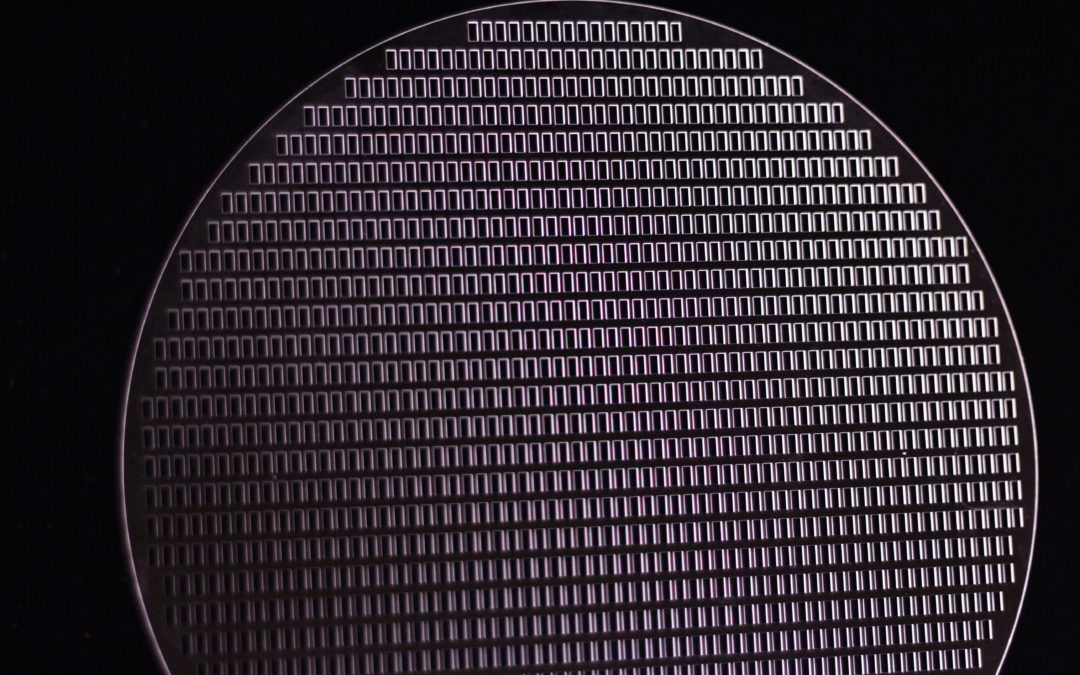

Semiconductor

Automotive

Defense

Aerospace

Medical

Life Sciences

Telecommunications

MACHINING SOLUTIONS WITH ENDLESS APPLICATIONS

Read below to learn more about just some of the application solutions we’re providing our clients.

UNIQUE CAPABILITIES BEYOND

TRADITIONAL MACHINING

We have meticulously refined our proprietary capabilities to deliver viable solutions to complex engineering problems. Our Sales Engineers collaborate with you to identify which machining capability fits your project best.

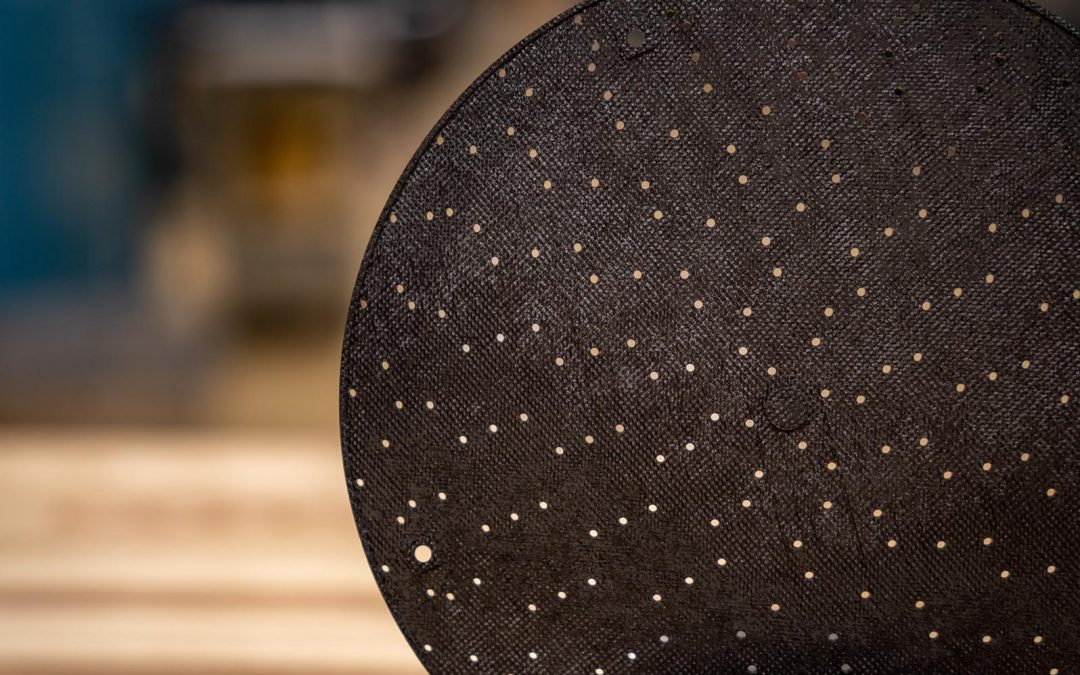

ULTRASONIC MACHINING

The world’s leading Ultrasonic Machining company, Bullen provides a superior solution to traditional machining when your design requires a feature or pattern in certain hard, brittle, & specialty materials.

Explore Ultrasonic Machining >

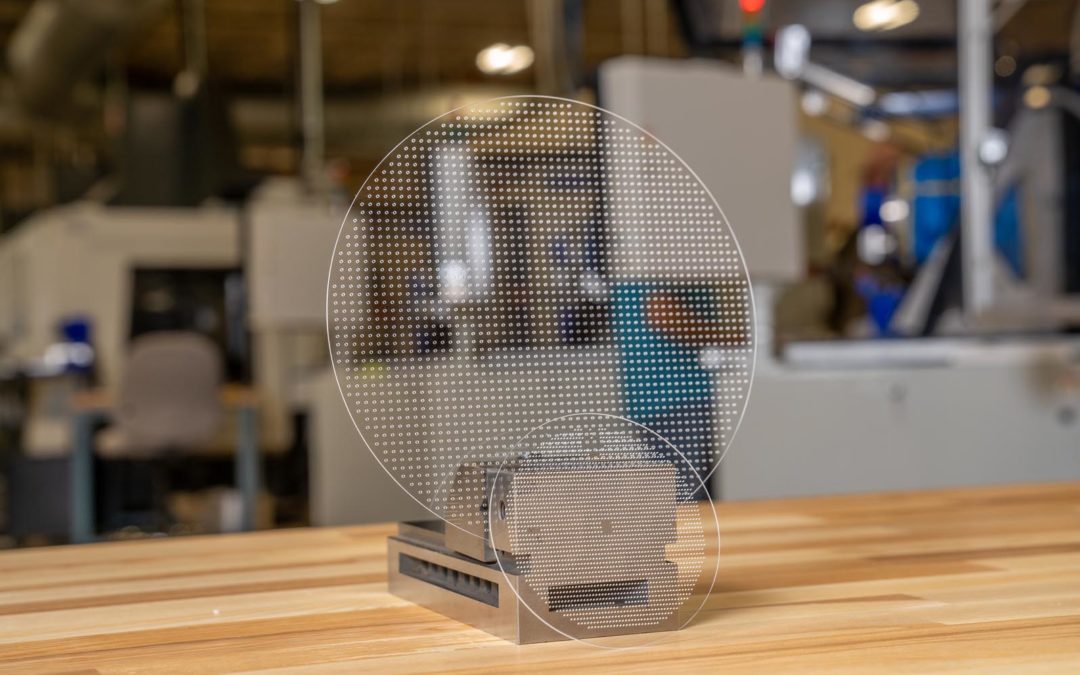

MICROLUCENT® MACHINING

Bullen uses unique laser technology to cut precise features in transparent materials. This proprietary technology lowers costs while improving the quality of cuts.

Explore Microlucent® Machining >

PARTNERING WITH

GLOBAL ADVANCED TECHNOLOGY COMPANIES

FOR OVER 50 YEARS

Fortune 50 Companies

Aerospace & Defense Companies

Mems & Microsystem Developers

Medical & Life Sciences Organizations

Semiconductor Equipment Manufacturers

News

When looking to take the first step towards your engineering career or a career in manufacturing, there are many options. Some paths include: Technical training with a pre-apprenticeship or internship. Apprenticeship with focus on specific education and on-the-job training. College degree with internships Each of these paths open opportunities for an engaging and exciting career […]