(NON)TRADITIONAL MACHINING SERVICES

Bullen provides unique machining solutions to help your design come to life when traditional machining services can’t.

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

UNIQUE CAPABILITIES BEYOND TRADITIONAL MACHINING

We have meticulously refined our proprietary capabilities to deliver viable solutions to complex engineering problems. Our Sales Engineers collaborate with you to identify which machining capability fits your project best.

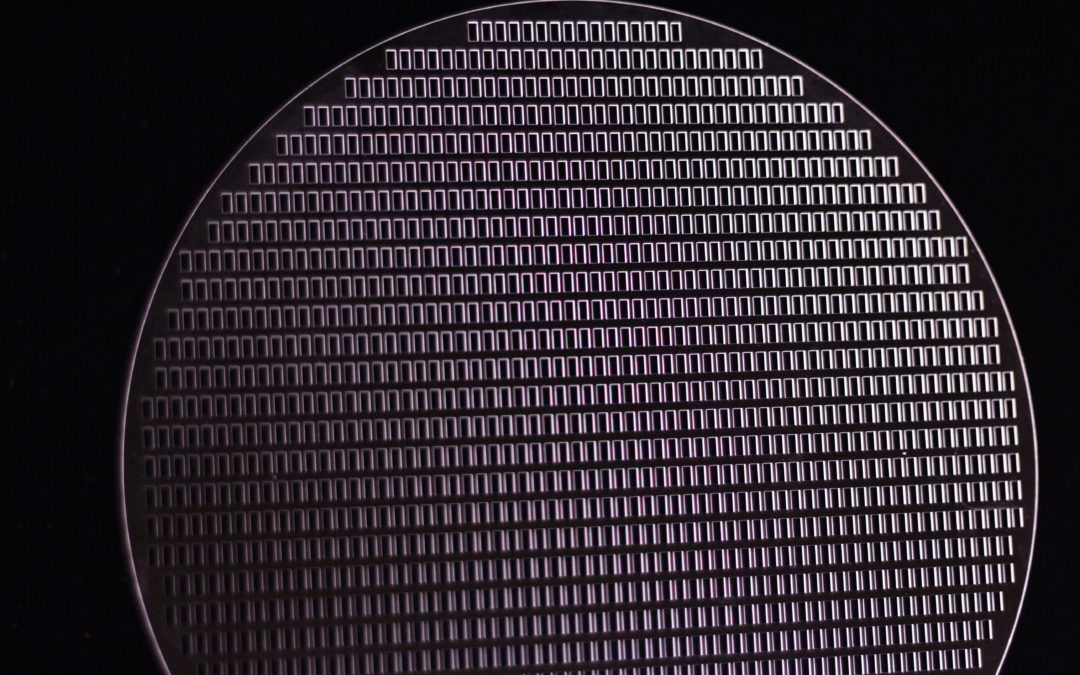

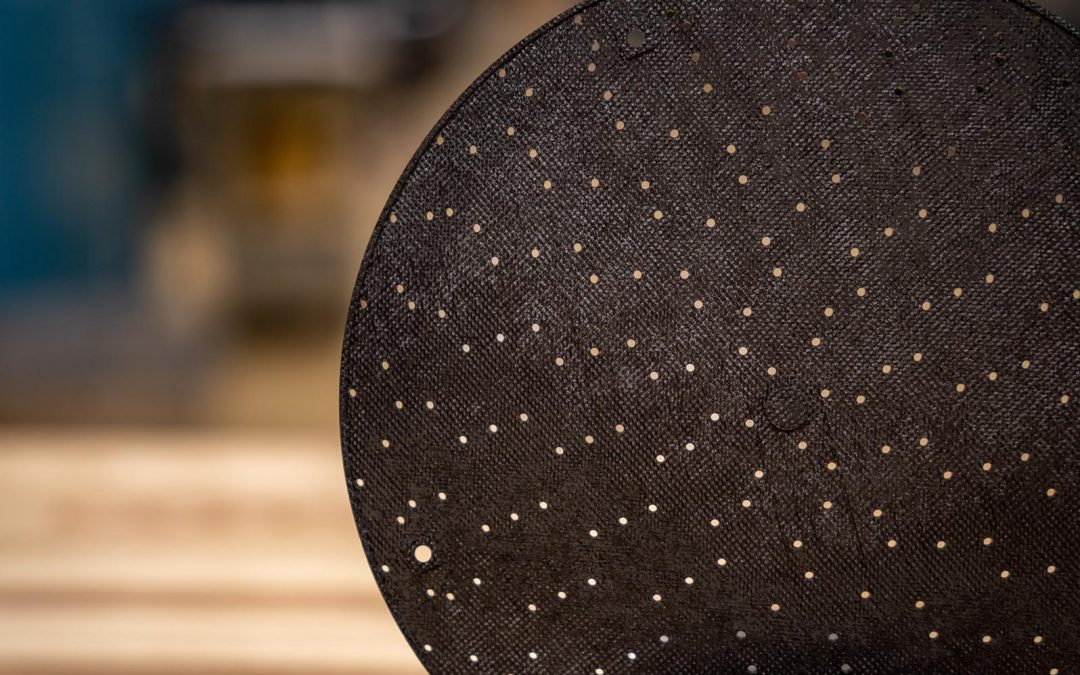

ULTRASONIC MACHINING

The world’s leading Ultrasonic Machining company, Bullen provides a superior solution to traditional machining when your design requires a feature or pattern in certain hard, brittle, & specialty materials.

Explore Ultrasonic Machining >

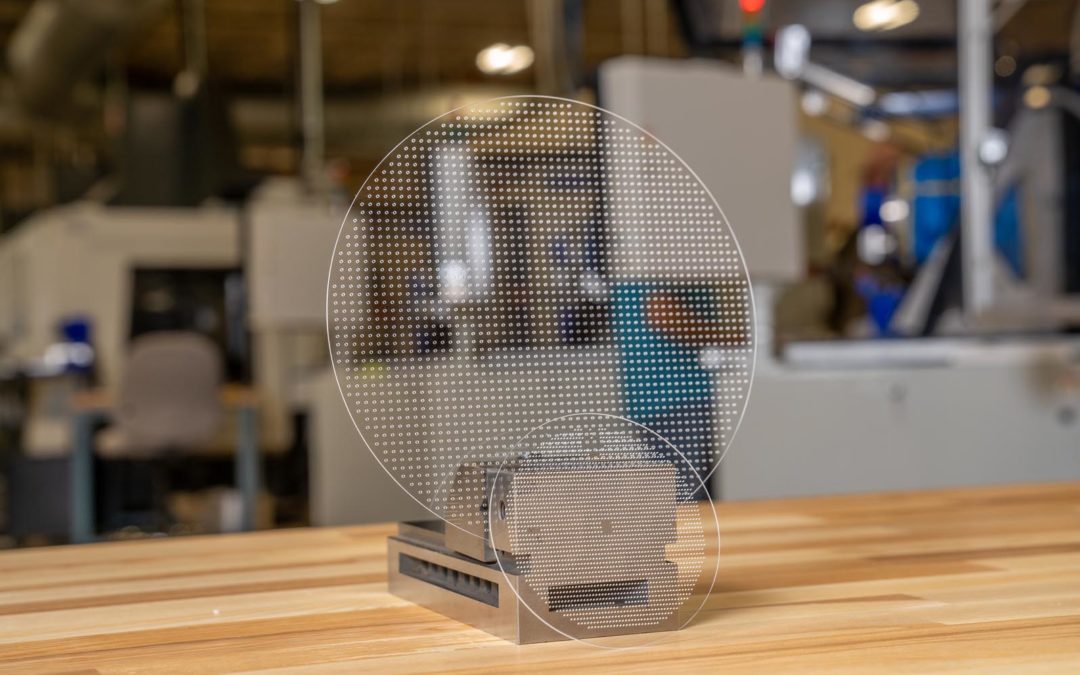

MICROLUCENT® MACHINING

Bullen uses unique laser technology to cut precise features in transparent materials. This proprietary technology lowers costs while improving the quality of cuts.

Explore Microlucent® Machining >

PARTNERING WITH

GLOBAL ADVANCED TECHNOLOGY COMPANIES

FOR OVER 50 YEARS

Fortune 50 Companies

Aerospace & Defense Companies

Mems & Microsystem Developers

Medical & Life Sciences Organizations

Semiconductor Equipment Manufacturers

Materials We Machine

Glass

Fused Silica: HPFS® Corning 7980, Schott Lithosil®

Quartz

BK7, Soda Lime, and other glass materials

Glass Ceramics

Macor

ULE Glass

Technical Ceramics

Aluminum

Nitride

Boron Carbide

Silicon Carbide

Silicon Nitride

Zirconia

Yttria

Sialon

Ferrite

Titanium Nitride

Engineered Ceramics

Converted SiC

PCD

Ceramic Composites (CMC)

Single Crystals

Germanium

Sapphire

Spinel

SiC

Calcium Fluoride

Engineered Plastic

PMMA

Bismaleimide

Polystyrene

Polycarbonate

A SIMPLE PROCESS TO SOLVE YOUR

COMPLEX ENGINEERING NEED

1. Talk To Our Team

Click “talk to our team” to get in touch today via phone, email, or an RFQ. Describe your design, budget, and timeline, and one of our Sales Engineers will get back to you quickly - most of the time, on the same day. If we’re not the right fit, we promise to point you in the right direction.

2. Plan

We leave no stone unturned during our planning process. Bringing in our engineers, R&D team, and technical support staff, we review your design or concept and work with you to understand your unique requirements. In this phase, we often collaborate with clients to reduce product realization times and costs without sacrificing superior quality. We then prepare a project proposal for your review.

3. Prototype & Pilot Production

We know your time is valuable. That’s why your dedicated Sales Engineer will serve as your advocate, ensuring your custom prototype is delivered on time and to your quality standards. We are already evaluating what final production will look like in this phase, applying innovative solutions to ensure future efficiencies and reduced costs.

4. Produce

Congrats - another job well done! It’s time to transform your prototype part into volume production. Did you know that we can custom-build machines and tools for higher-volume clients to drive down your cost? No matter what path we choose, you can rest assured we are working with your best interest in mind and with the same support and quality inspection that got us to this point. Time to check this box and move on to your next challenge!

The Bullen Committment

HERE’S WHAT YOU CAN EXPECT WHEN YOU WORK WITH BULLEN…

A CONFIDENTIAL ENVIRONMENT

While we’d love to boast on the fantastic things our clients are doing, we know that your confidence is of utmost importance. You can rest assured that your production and design are always fully confidential.

FULL TRANSPARENCY IN PRICING & PRODUCTION

No hidden fees, no last-minute surprises. When you engage with our team, we promise to be upfront and provide a clear path to your production. If we aren’t the right fit for your project, we’ll point you in the right direction.

THE ABILITY TO SCALE

Know you’re taken care of every step of the way – from concept to mass production. Our team at Bullen always begins with final production in mind, often custom building machines for our higher-volume clients so they can drive down cost and increase efficiencies.

News

When looking to take the first step towards your engineering career or a career in manufacturing, there are many options. Some paths include: Technical training with a pre-apprenticeship or internship. Apprenticeship with focus on specific education and on-the-job training. College degree with internships Each of these paths open opportunities for an engaging and exciting career […]